CK3M and CK5M

Programmable Multi-Axis Controller

Multi-axis control with a fastest servo cycle time of 50 µs/5 axes enables precision machining

- Scalable Motion Controller CPU Range:

CK3M (1.0 GHz, 2 Cores), CK5M (1.6GHz, 4 cores) - Local axes for nanoscale precision

- Ultra high-speed synchronous control (50µs/5 axes)

- Custom servo regulation algorithms

- Flexibility on using multi-vendor actuators and encoders

- Flexible programming with G-code, ANSI C and PMAC Script languages

- EtherCAT for flexible configuration

- Standard TCP/IP Ethernet communication

- Open Protocols: MQTT publisher/subscriber and OPC-UA server, Ethernet IP Adapter and Modbus TCP Client/Server

- Modular design and DIN rail mounting

Specifications & ordering info

| Product | Type of module | CPU clock frequency | Max. number of axes via EtherCAT | Max. number of axis interface units | Amplifier interface | Encoder interface | Digital output type | Number of digital inputs | Number of digital outputs | Number of analog inputs | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

CK3M Motion Control CPU | 1.0 GHz | 0 | 4 | 0 | 0 | 0 | CK3M CPU, 1 GB RAM, 1 GB Flash, No EtherCAT. Up to two axis interface units can be connected. Expansion units can be connected. |

|

|||

|

|

CK3M Motion Control CPU | 1.0 GHz | 4 | 4 | 0 | 0 | 0 | CK3M CPU, 1 GB RAM, 1 GB Flash, 4 EtherCAT axes. Up to two axis interface units can be connected. Expansion units can be connected. |

|

|||

|

|

CK3M Motion Control CPU | 1.0 GHz | 8 | 4 | 0 | 0 | 0 | CK3M CPU, 1 GB RAM, 1 GB Flash, 8 EtherCAT axes. Up to two axis interface units can be connected. Expansion units can be connected. |

|

|||

|

|

Analog I/O | 4 | CK3W Analog IN, 4 points, +/-10 V, 16 bit (full scale) |

|

||||||||

|

|

Analog I/O | 8 | CK3W Analog IN, 8 points, +/-10 V, 16 bit (full scale) |

|

||||||||

|

|

Axis interface | DirectPWM output | Digital quadrature / Serial | NPN | CK3W 4 Axis Interface Unit, Digital encoder, DirectPWM, NPN |

|

||||||

|

|

Axis interface | DirectPWM output | Digital quadrature / Serial | PNP | CK3W 4 Axis Interface Unit, Digital encoder, DirectPWM, PNP |

|

||||||

|

|

Axis interface | Filtered PWM | Digital quadrature / Serial | NPN | CK3W 4 Axis Interface Unit, DA output (Filtered PWM), Pulse + direction or phase difference, Pulse encoder / Serial encoder, NPN Output type |

|

||||||

|

|

Axis interface | Filtered PWM | Digital quadrature / Serial | PNP | CK3W 4 Axis Interface Unit, DA output (Filtered PWM), Pulse + direction or phase difference, Pulse encoder / Serial encoder, PNP Output type |

|

||||||

|

|

Axis interface | True DAC | Digital quadrature / Serial | NPN | CK3W 4 Axis Interface Unit, DA output (True DAC), Pulse + direction or phase difference, Pulse encoder / Serial encoder, NPN Output type |

|

||||||

|

|

Axis interface | True DAC | Digital quadrature / Serial | PNP | CK3W 4 Axis Interface Unit, DA output (True DAC), Pulse + direction or phase difference, Pulse encoder / Serial encoder, PNP Output type |

|

||||||

|

|

Axis interface | DirectPWM output | Sinusoidal / Serial | NPN | CK3W 4 Axis Interface Unit, Sinusoidal encoder, DirectPWM, NPN |

|

||||||

|

|

Axis interface | DirectPWM output | Sinusoidal / Serial | PNP | CK3W 4 Axis Interface Unit, Sinusoidal encoder, DirectPWM, PNP |

|

||||||

|

|

Encoder input | Not Applicable | Special Serial Protocol | Encoder Input Unit for CK3M, Serial encoder 4 channels, BiSS-C, Endat2.2, and R88M-1Lx/-1Mx Motor built-in encoder |

|

|||||||

|

|

Laser interface | Not Applicable | Not Applicable | PWM, XY2-100 | Laser Interface Unit for CK3M, XY2-100 Protocol, Laser PWM output |

|

||||||

|

|

Laser interface | Not Applicable | Not Applicable | PWM, TCR, XY2-100 | Laser Interface Unit for CK3M, XY2-100 Protocol, Laser PWM output and TCR Output |

|

||||||

|

|

Laser interface | Not Applicable | Not Applicable | PWM, SL2-100 | Laser Interface Unit for CK3M, SL2-100 Protocol, Laser PWM output |

|

||||||

|

|

Laser interface | Not Applicable | Not Applicable | PWM, SL2-100, TCR | Laser Interface Unit for CK3M, SL2-100 Protocol, Laser PWM output and TCR Output |

|

||||||

|

|

Digital I/O | NPN | 16 | 16 | CK3W Digital IO, IN/OUT:16/16, NPN |

|

||||||

|

|

Digital I/O | PNP | 16 | 16 | CK3W Digital IO, IN/OUT:16/16, PNP |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts CK3M and CK5M

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for CK3M and CK5M

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Modular design

The modular design allows you to freely combine the CK3M or CK5M.

CK3M vs. CK5M

Both CK3M and CK5M are advanced motion controllers with identical functionality. The key difference lies in their core processors: CK3M features a 1.0 GHz dual-core processor, while CK5M is equipped with a more powerful 1.6 GHz quad-core processor.

| Max. Local axes | Max. Ethercat axes | |

|---|---|---|

| CK3M | 16 | 8 |

| CK5M | 32 | 32 |

Power PMAC IDE (Integrated Development Environment)

- Based on Microsoft® Visual Studio®

- G-code, ANSI C and PMAC Script languages

- Easy tuning

- Simple setting

- Troubleshooting

- Debugger

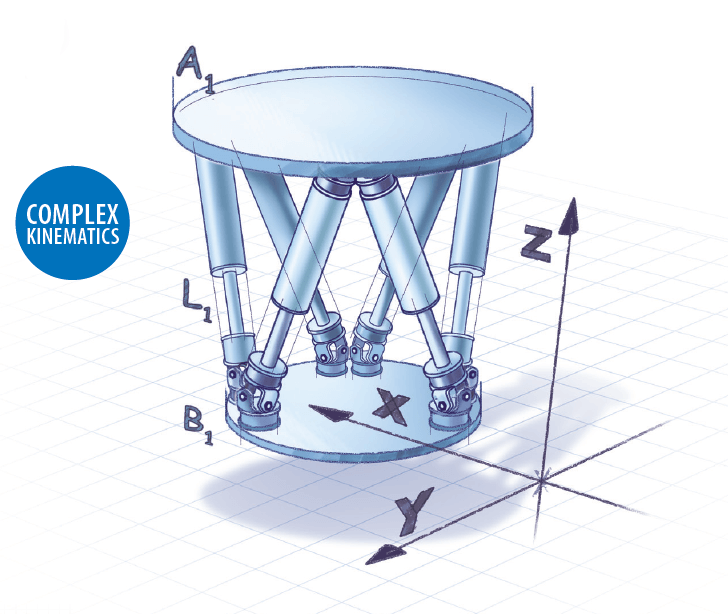

Complex kinematics

Complex mechanics can be controlled thanks to the matrix handling and the space conversion. Special applications like Hexapod telescope mirror positioning, can be easily operated by the kinematics handling functionality.

Leveraging features for accurate machining application

G-Code

Standard RS-274 G-Code interpreter. User-writable subroutines for customized implementation of G, M, T and D-codes. Flexibility to adapt the syntax and to work in combination with any CAD/CAM software.

Cutter compensation 2D/3D

Tool diameter and shape compensation, matching the cutting point exactly as specified in G-Code.

Fast processor + large program buffer

Fast processor can handle over 10,000 blocks per second and up to 1Gb part programs.

Block Retrace for reversing the path

Path can be reverted in order to remove the tool from cutting area.

Advanced Block Lookahead

Instructions in the buffer are analyzed in advance, movements are blended and optimized in speed and acceleration for a better performance.

Tangent tool management

Tools with a cutting direction require a tangent path positioning.

Software

Power PMAC IDE

This computer software is used to configure, create user programs, and debug the programs for the NY51-A, CK3E and CK3M Programmable Multi Axis Controllers.

_getting_started_guide_en.jpg)