How IO-Link simplifies sensor-level communication

Address key challenges

Reduce start-up time:

Minimize downtime by predictive maintenance:

Streamline setup changes:

Discover how IO-Link can transform your operations by improving reliability and efficiency.

Explore our IO-Link compliant solutions

-

Proximity Sensor E2E NEXT

-

Metal Face Proximity Sensors

-

Advanced direct reflective photoelectric sensors

-

Long-range Time-of-Flight sensor

-

High-performance color mark sensor

-

General purpose sensor in compact plastic housing

-

IoT Flow Sensors

-

IoT Pressure Sensors

-

ALL in ONE Line-Up

-

IO-Link master unit for water and dusty environments

-

Convert analogue signals with high precision and output via IO-Link communication

-

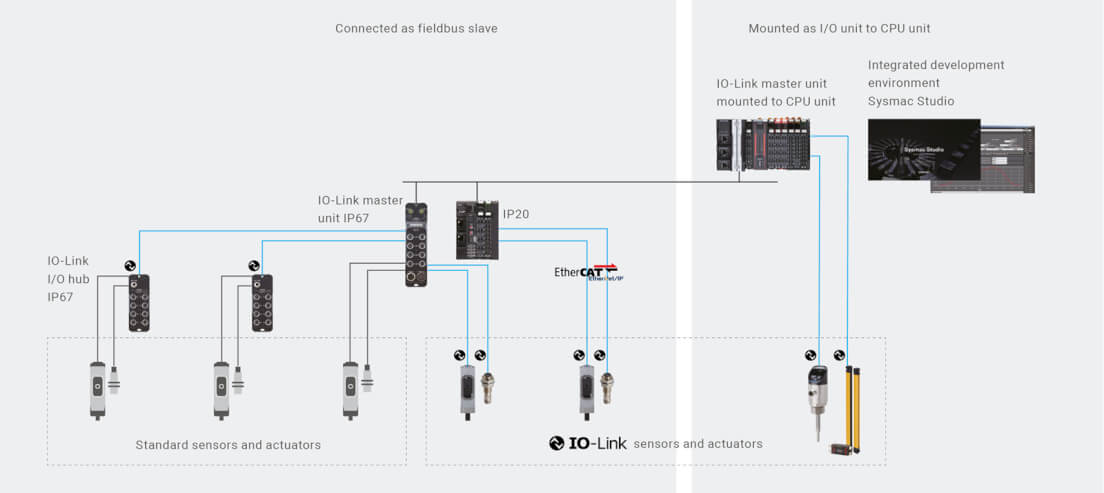

Modular IP20 IOs

-

Compact in size, powerful in functionality

-

Remote IP67 IOs over Ethercat and Ethernet/IP networks with IO Link master functionality

-

Boost Your Productivity