NJ5

Sysmac controller – NJ5 Series

The NJ5 series is a machine controller for logic sequence and motion that includes CPU options for advanced functions such as robotics and database connection.

- Fastest cycle time: 500 µs

- Number of axes: 64, 32, 16

- Synchronized motion core

- Functions: Logic sequence, Motion, CNC, Robotics, Database connection, SECS/GEM and OPC-UA

- Database direct connection in V2.0 is expanded with stored procedure calls and secure communications functionality

- Database direct connection: SQL client for server Microsoft SQL, Oracle, IBM DB2, MySQL, Firebird, PostgreSQL

- Delta, SCARA and Cartesian robots control

- CNC functionality: Ideal for XY cutting, milling, lathe and any other path-following application such as dispensing, bending, grinding and forming machines

- Multi-tasking

- Built-in EtherCAT and EtherNet/IP ports

- EtherCAT Ring topology is supported to maintain communications and control in case of a broken cable or device failure

Specifications & ordering info

| Product | Max. number of synchronous axes | Supports DB connection | Supports SECS/GEM | Supports CNC | Primary task cycle time | Program memory | Variables memory | Communication port(s) | Max. number of remote I/O nodes | Supports sequence control | Supports motion control | Supports robotics control | Max. number of robots | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

16 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU, 20 mB memory, built-in EtherCAT (16 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

16 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU with Database Connectivity, 20MB memory, built-in EtherCAT (16 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

16 | No | Yes | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU with SECS/GEM communication, 20 MB memory, built-in EtherCAT (16 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

32 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU, 20 mB memory, built-in EtherCAT (32 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

32 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU with Database Connectivity, 20MB memory, built-in EtherCAT (32 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

64 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU, 20 mB memory, built-in EtherCAT (64 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

64 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CPU with Database Connectivity, 20MB memory, built-in EtherCAT (64 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

16 | Yes | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 4 | Sysmac NJ5 CPU with Robot kinematics, 16 axes, SQL client |

|

|

|

32 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 8 | Sysmac NJ5 CPU with Robot kinematics, (max 8 robots), 20MB memory, built-in EtherCAT (32 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

64 | No | No | No | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | Yes | 8 | Sysmac NJ5 CPU with Robot kinematics, (max 8 robots), 20MB memory, built-in EtherCAT (64 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP |

|

|

|

32 | No | No | Yes | 0.5 ms | 20 MB | 6 MB | EtherCAT Master, EtherNet/IP, USB | 192 | Yes | Yes | No | 0 | Sysmac NJ5 CNC CPU, 20MB memory, built-in EtherCAT (32 servo axes, in total 192 EtherCAT nodes) and EtherNet/IP. USB license not included. |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts NJ5

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for NJ5

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadEtherCAT Redundancy

Redundancy minimizes downtime

Even if a part of the EtherCAT network is disconnected, Cable Redundancy provides continuous connectivity.

This function allows you to fix disconnection without stopping the machines and production line where one controller provides both machine control and safety control.

-

OMRON ECAT Improvement

02:03

OMRON ECAT Improvement

Software

Sysmac Studio - Integrated Development Environment

- A single tool for logic sequence, motion, safety, robotics, vision, HMI and Database connection

- Open standard IEC 61131-3

- Sysmac Library to optimize engineering time and machine availability

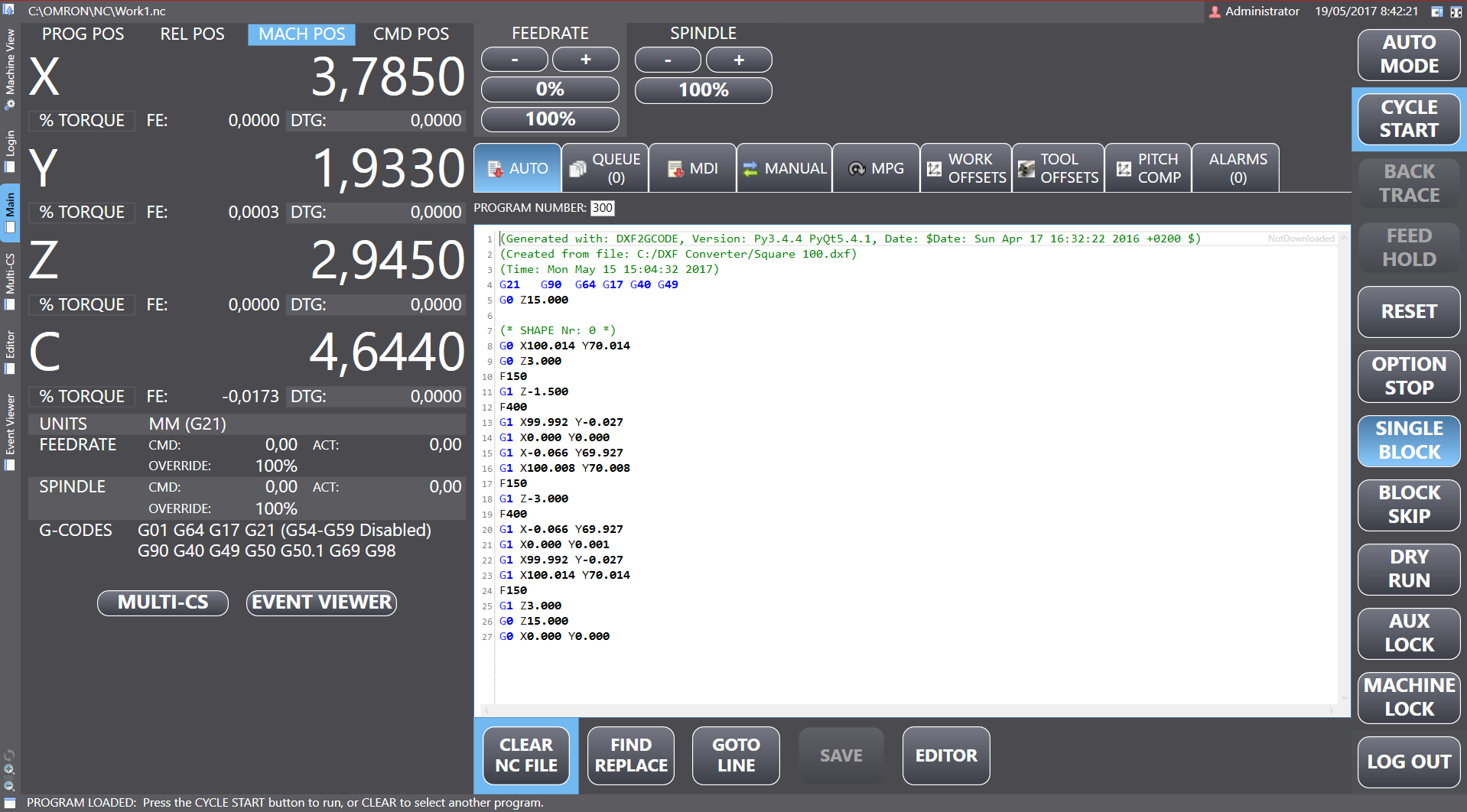

- G-Code File Editor

- Execution monitor Active G/M code display

- Command terminal

- Jogging, homing

- Customizable software allows adding functionality by the users (Requires CNC operator SDK version)

Videos

-

OMRON Sysmac Platform with CNC

Our Sysmac Platform now integrates the complete machine processes and CNC in one machine controller. It improves production efficiency, enables complex motion trajectories and reduces machine development environment.

03:17

OMRON Sysmac Platform with CNC

Our Sysmac Platform now integrates the complete machine processes and CNC in one machine controller. It improves production efficiency, enables complex motion trajectories and reduces machine development environment.

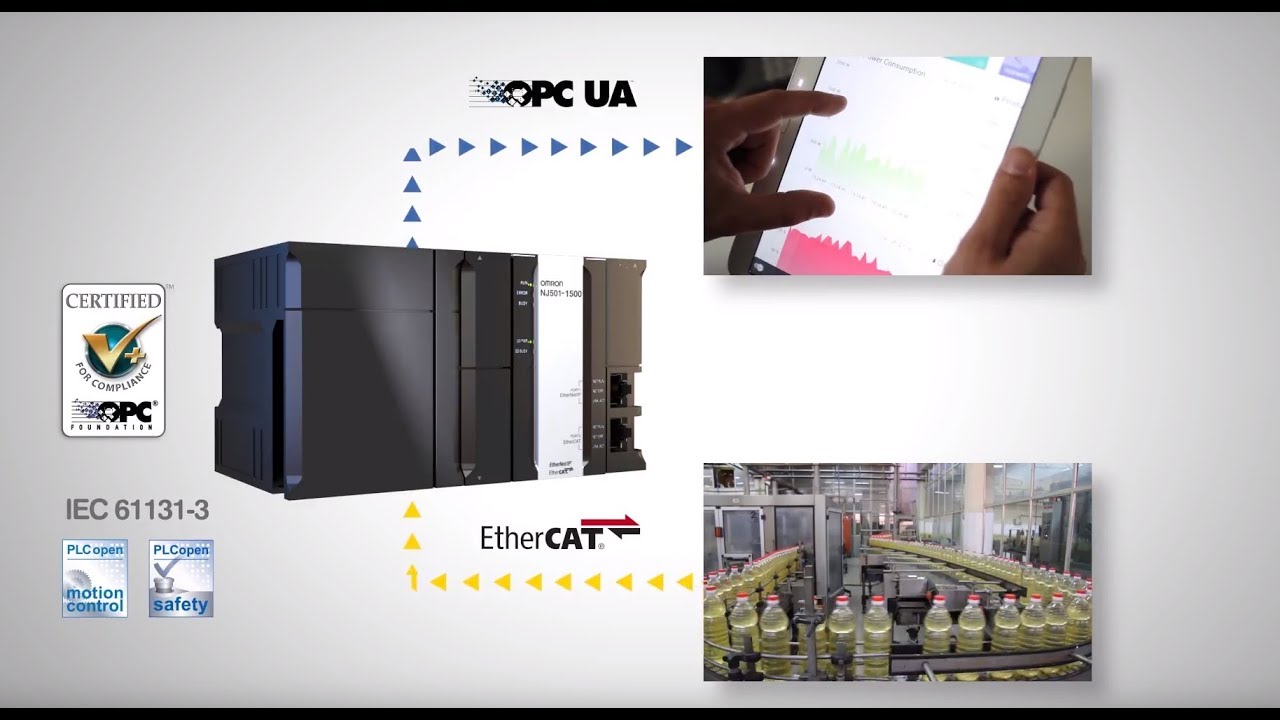

OMRON NJ5 Controller with OPC UA

Omron implements OPC UA as a standard feature.Related products

-

Sysmac general purpose servo

-

Higher Productivity and Safer Environment

-

From basic Analogue I/O to advanced temperature control

-

Open to any communication

-

8 to 64 points per unit - input, output or mixed

-

Add motion control to any CJ-Series PLC

-

XS5 XS2 XS6 Series

-

NA Series -The Sysmac HMI

-

Modular IP20 IOs

-

Integrated safety into machine automation

-

Secure and Easy Remote Access to your machines

-

For applications requiring high-speed processing for machine control, safety, reliability and maintainability.

-

Boost Your Productivity

_cg_en.jpg)

_cg_en.jpg)

-ect_vision_sensor_cg_en.jpg)

_cg_en.jpg)

_ac58-series_absolute_encoder_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

-x)_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)

_cg_en.jpg)