K6CM-VBM

Motor Condition Monitoring Device – vibration monitoring

K6CM-VBM controller analyses vibrations detected on electric motors to monitor the entire motor’s driveline health status, suggesting maintenance before serious issues occur, and therefore avoiding unplanned intervention and costly downtime.

This technology allows to:

- Be very effective in detecting motor’s bearing-related damages, thank to time and frequency domain analysis

- Easily setup on both greenfield and brownfield machines, as parametrization is done through a user friendly software interface, which allows to set the device in a couple of minutes

- Be able to detect anomalies such as load unbalance, misaligned belts, rotor and stator issues

- notifications in case of warning/alarm,

- remote monitoring

- interaction with custom applications and MQTT server.

Specifications & ordering info

| Product | Supply voltage AC | Supply voltage DC | Description | |

|---|---|---|---|---|

|

|

100-240 V | Motor Condition Monitoring, AC, 3-phase, Induction motor, Vibration & temperature model, 100 to 240 VAC, Transistor control output, Push-in Plus, LCD display, Ethernet IP |

|

|

|

|

20.4-26.4 V | 20.4-26.4 V | Motor Condition Monitoring, AC, 3-phase, Induction motor, Vibration & Temperature model, 24 VAC/VDC, Transistor control output, Push-in Plus, LCD display, Ethernet IP |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts K6CM-VBM

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for K6CM-VBM

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeature

K6CM-VBM, particularly suited to detect bearings-related abnormalities, monitors changes in vibration speed and accelerations and alerts in advance, before serious issue occur, allowing to properly plan maintenance interventions.

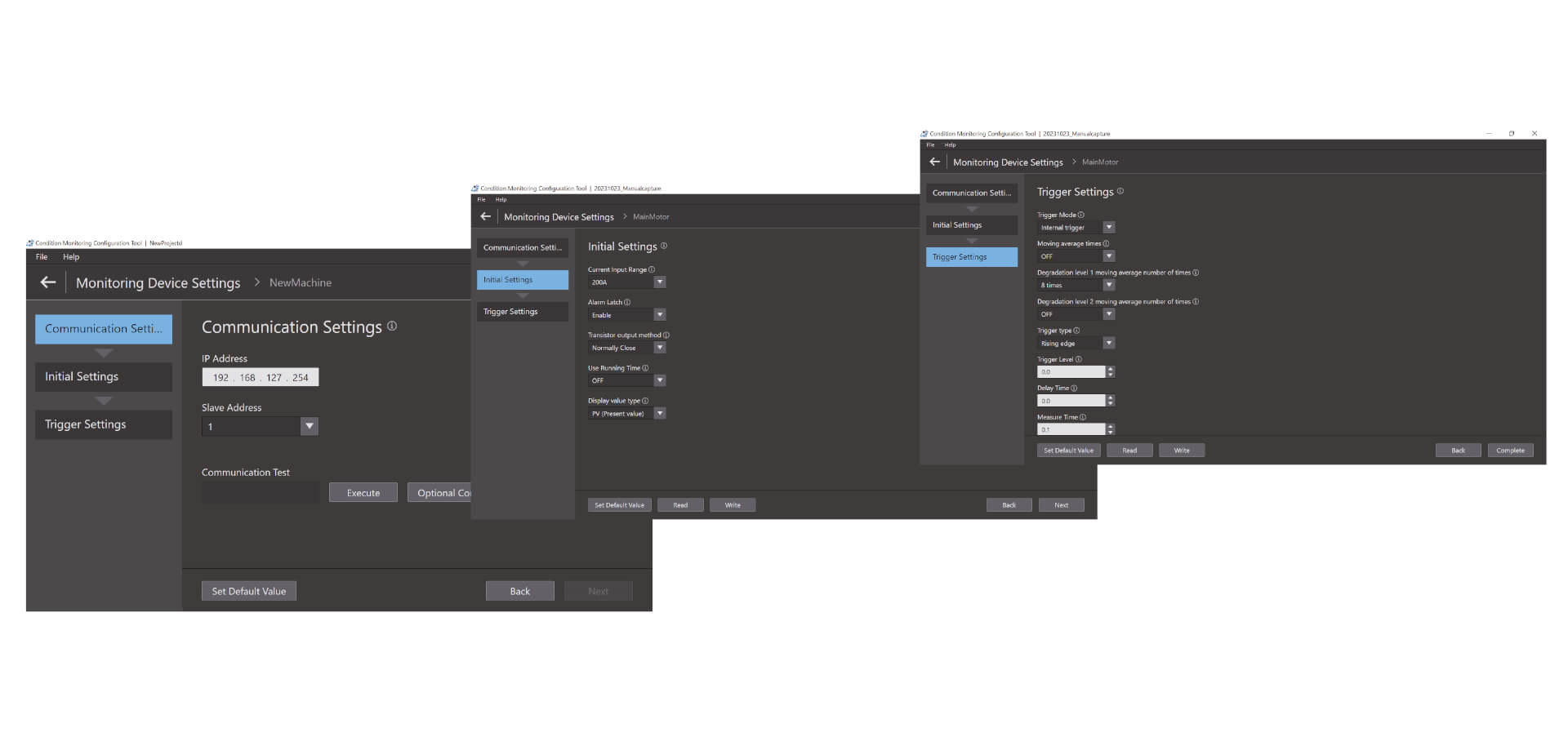

Condition monitoring devices can be configured with a single tool

Easy three-step configuration The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort

Easy three-step configuration

The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort. Setup can be completed in just three steps: communications setup, initial setup, and trigger setup.*1 With its high operability, the tool boosts on-site productivity as well.

Videos

-

K6CM Motor Condition Monitoring Device

K6CM takes the burden of monitoring motors off maintenance engineers. Motors can be maintained in advance of failure due to deterioration. K6CM (comprehensive current diagnosis type) can consistently monitor motor conditions by observing the current waveform of the motor. Additionally, you can understand the motor's maintenance timing without depending on an engineer, because K6CM provides threshold value setting.

02:40

K6CM Motor Condition Monitoring Device

K6CM takes the burden of monitoring motors off maintenance engineers. Motors can be maintained in advance of failure due to deterioration. K6CM (comprehensive current diagnosis type) can consistently monitor motor conditions by observing the current waveform of the motor. Additionally, you can understand the motor's maintenance timing without depending on an engineer, because K6CM provides threshold value setting.

-

K6CM Demo Video

05:48

K6CM Demo Video

Solutions

Stand Alone installation (Without PLC)

This simple solution allows to:

- Monitor the status of the motor through the onboard LED, or through to the Condition Monitoring Software

- Setup the controllers through the Condition Monitoring Software, provided with the device

- Interface the K6CM with any external I/O devices (dig. Output)

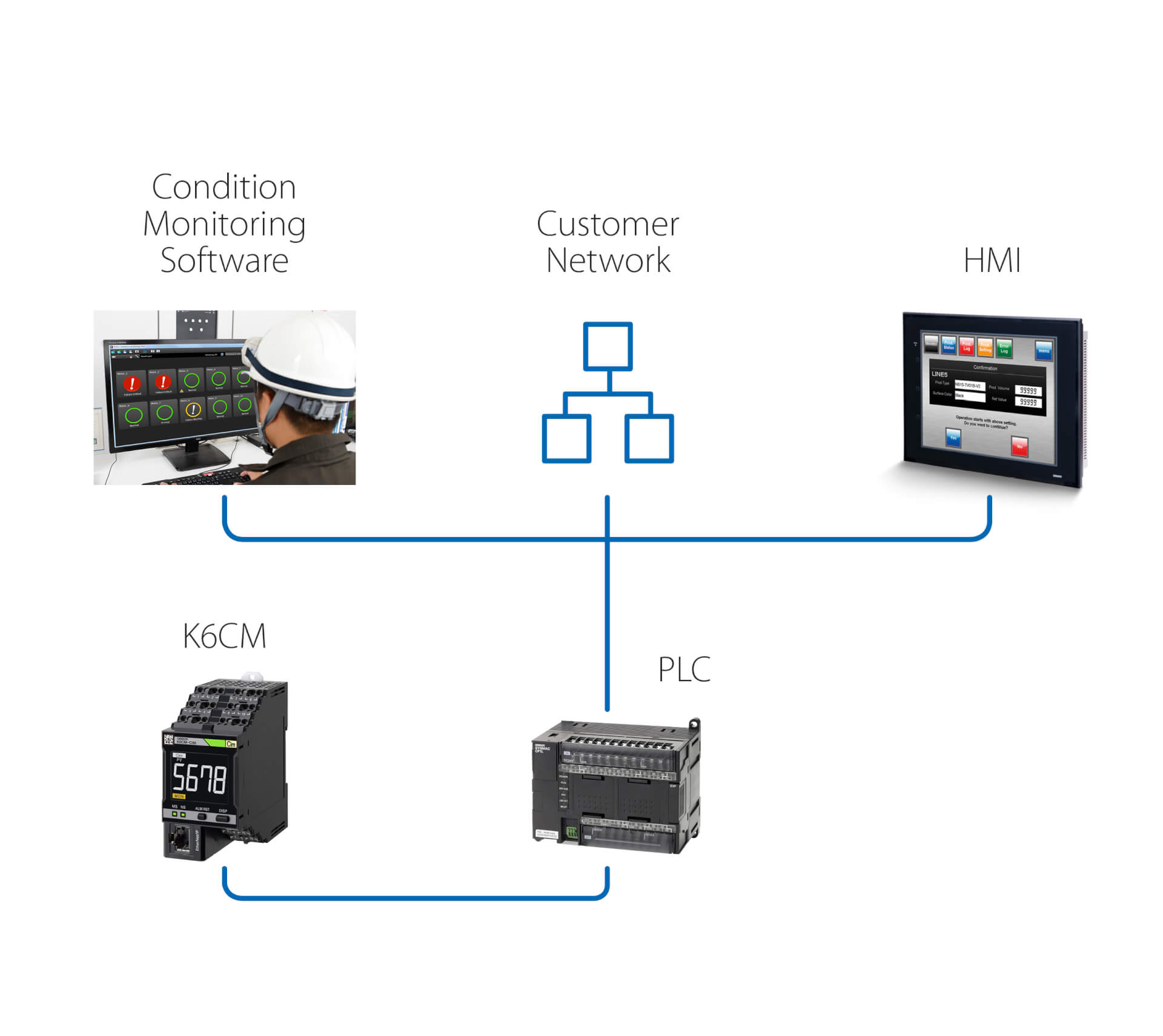

Stand Alone installation (with PLC)

This solution enables, in addition of the previous solution, to:

- Monitor the status of the motor through to the Condition Monitoring Software, running on a PC which is connected through a PLC

- Trigger, through the PLC, actions following any warning/alarm detected by K6CM

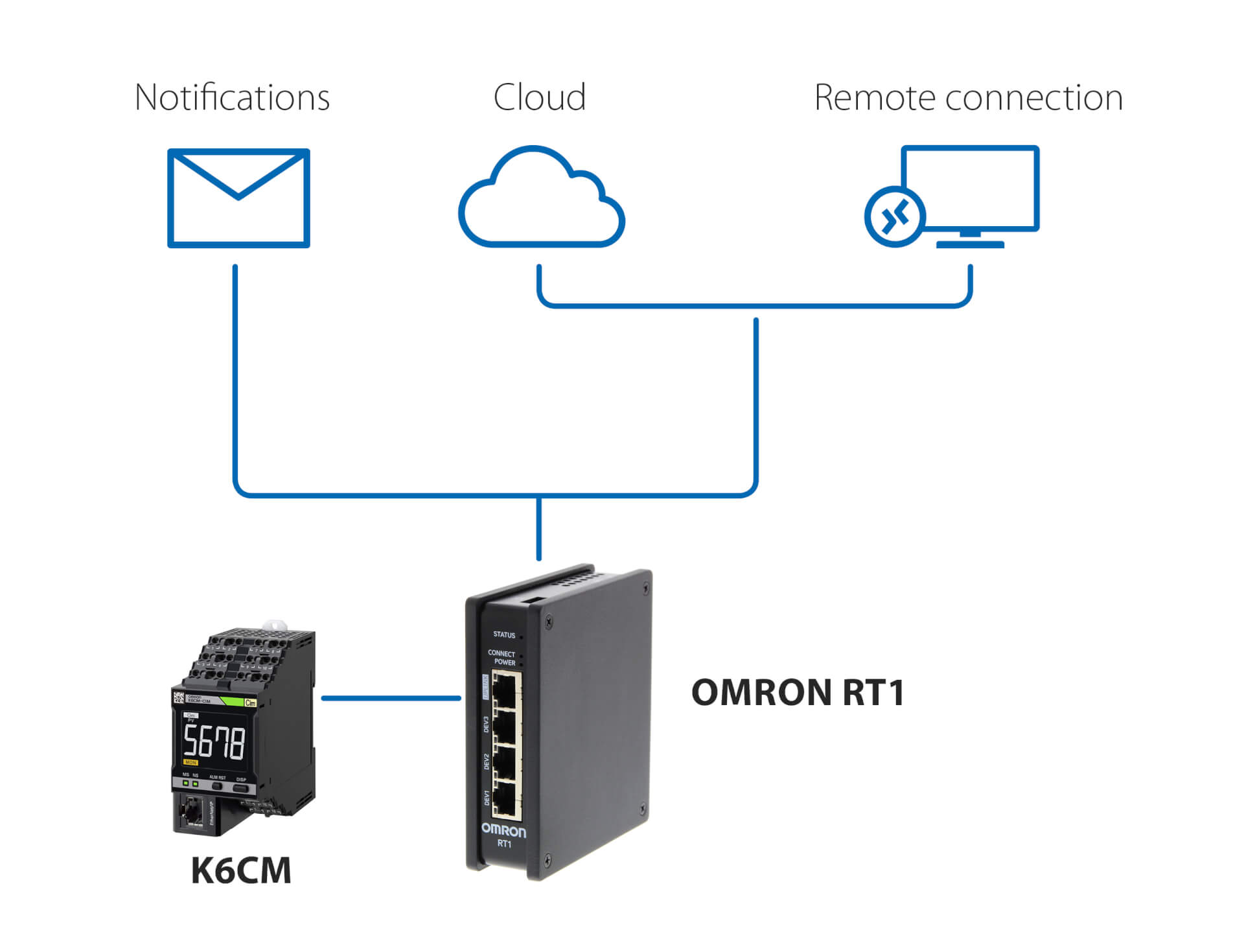

Notifications and remote monitoring - without PLC

This solution, using Omron RT1 as a gateway, enables:

- e-mail/SMS notifications in case anomalies are detected by K6CM

- secure connection (managed by RT1) to cloud, either via LAN or via 4G connection

- secure connection for remote monitoring and setup of K6CM, using the Condition Monitoring software provided with the controller

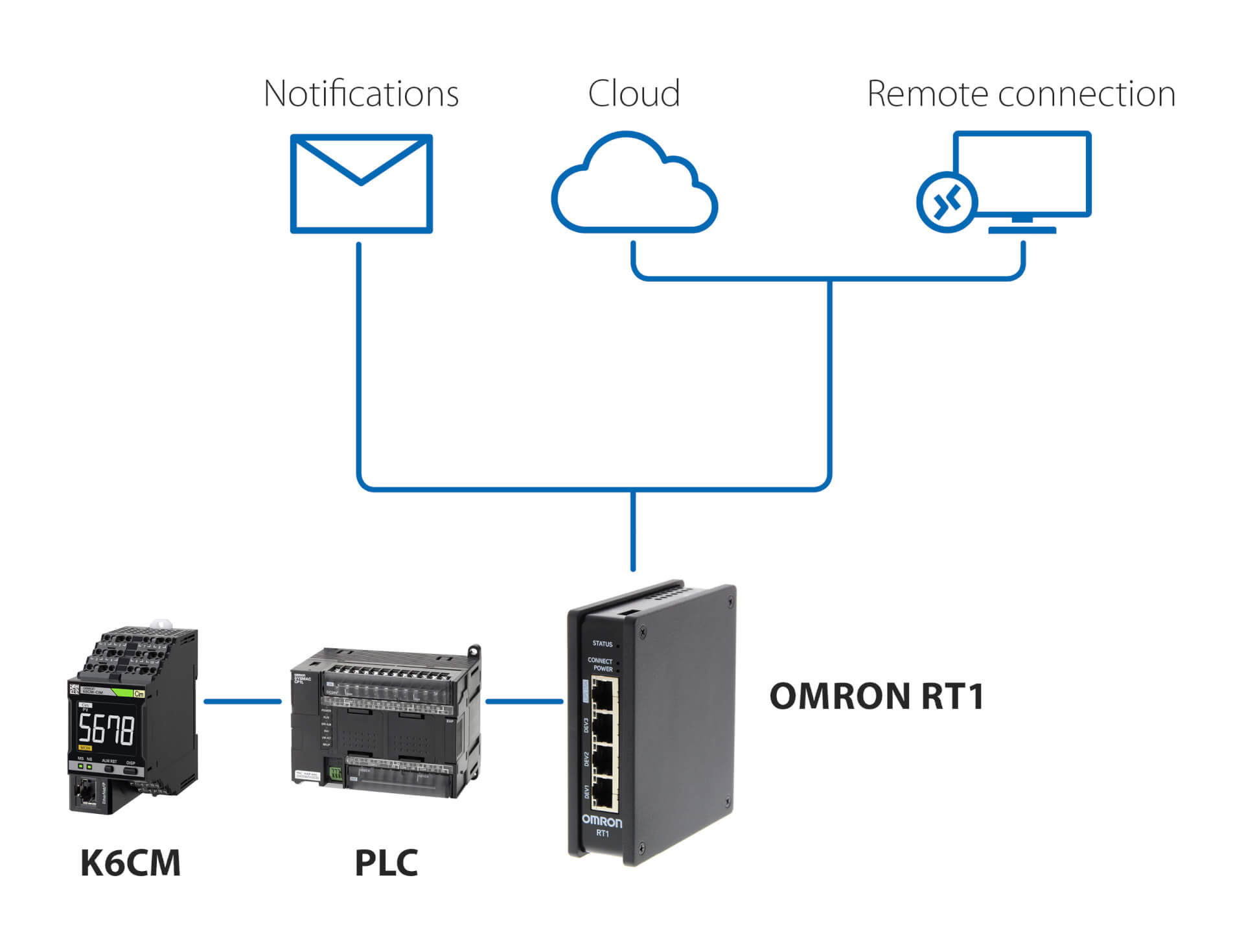

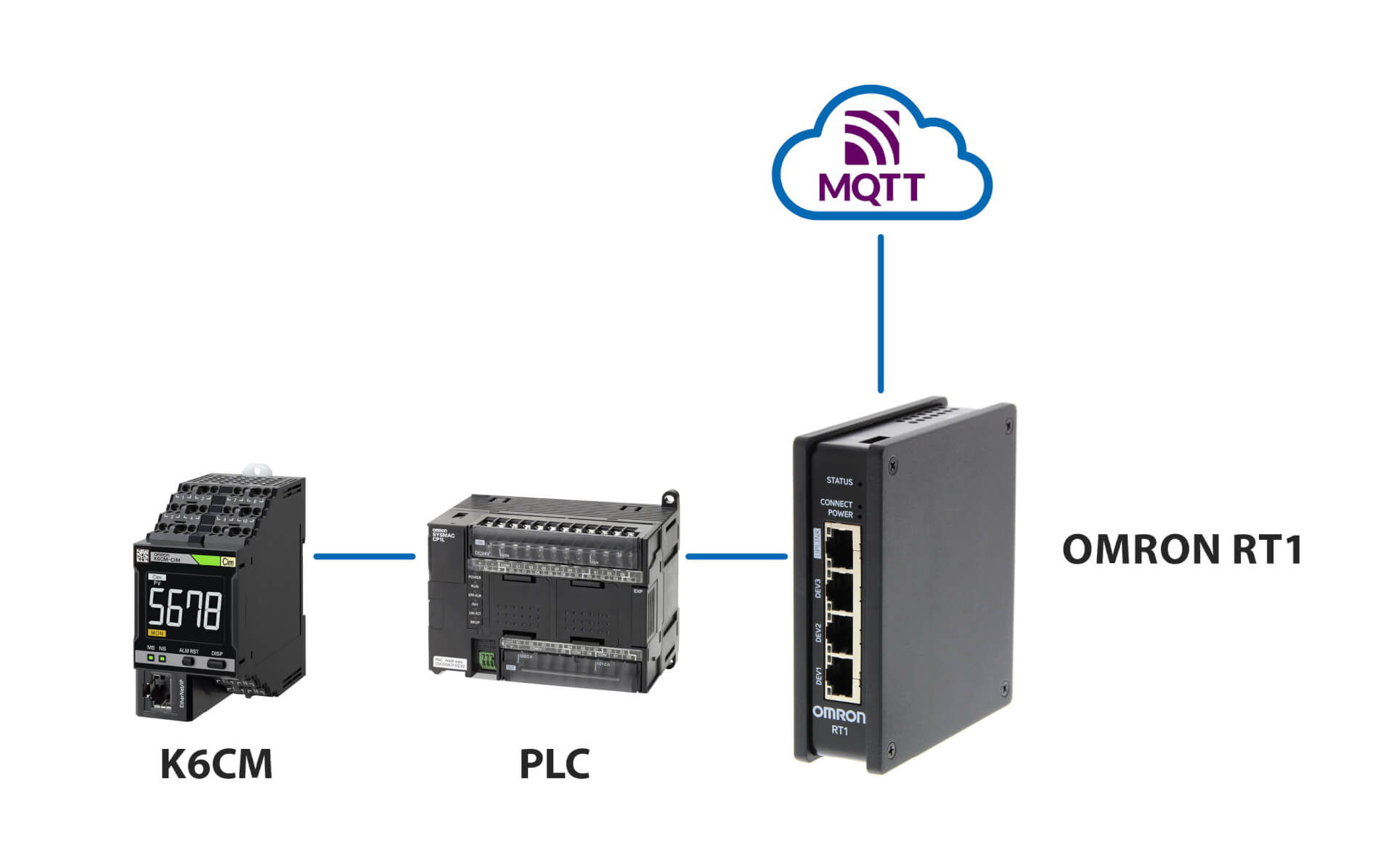

Notifications and remote monitoring – with PLC

This solution, using any PLC and Omron RT1 as a gateway, enables:

- e-mail/SMS notifications in case anomalies are detected by K6CM

- secure connection (managed by RT1) to cloud, either via LAN or via 4G connection

- secure connection for remote monitoring and setup of K6CM, using the Condition Monitoring software provided with the controller