Our i-BELT Data Services assist in linking the production and management challenges with manufacturing data. The data is turned into meaningful information to achieve practical improvements and to solve your production challenges

Co-creation

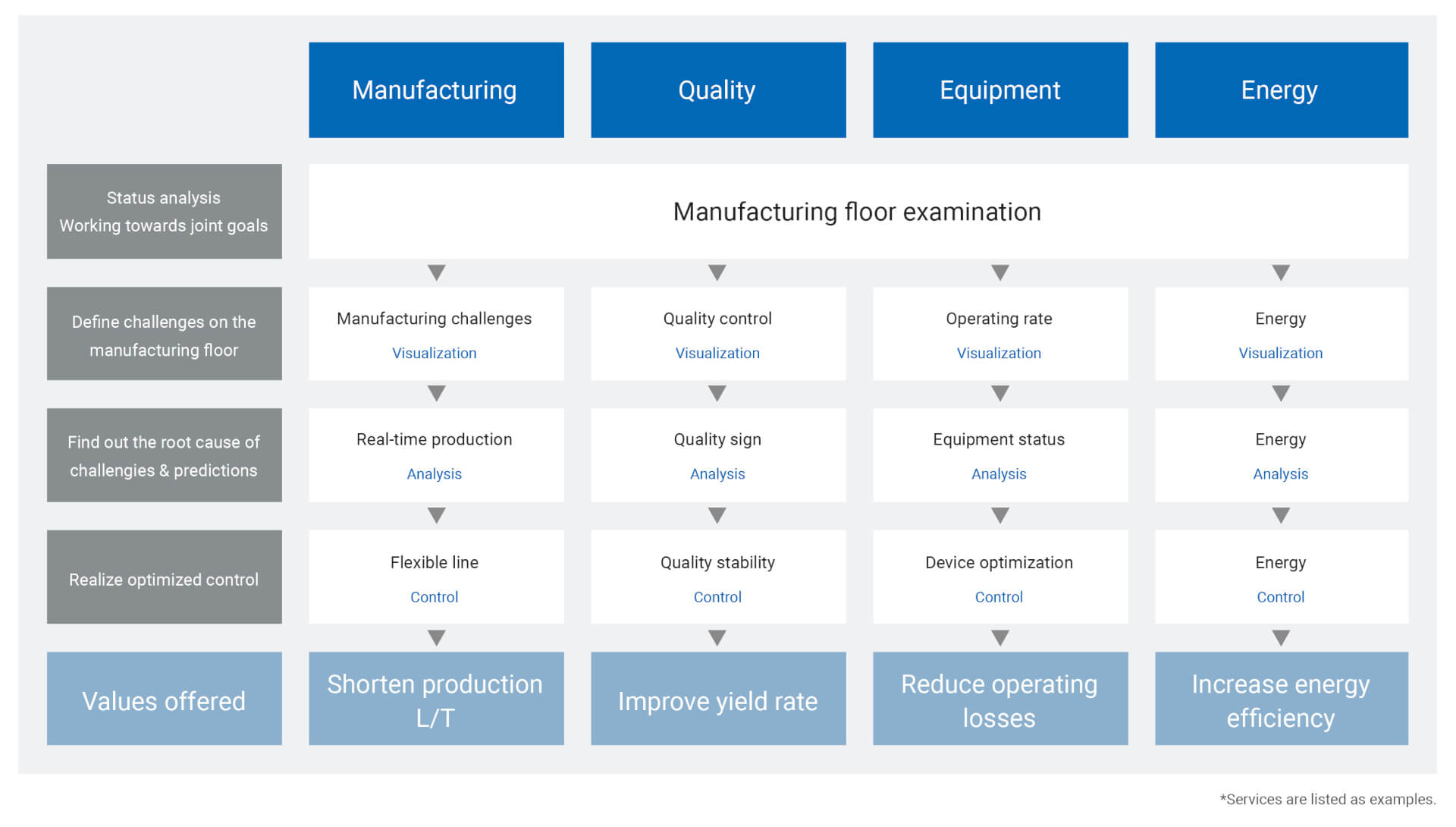

i-BELT Data Services Matrix

i-BELT data service process

In order to simplify the efforts from both sides, we follow a step-by-step approach so that we understand customer’s challenges deeply and plan the future roadmap together with our customers while minimizing the initial investments for them.

Step 1: Assessment

- Understanding customer pains

- Assessment industry 4.0 maturity level

- Status analysis

- Evolution scenario discussion

Step 2: Data Collection

- Extensive data collection

- Data analysis

- Data validation/proof of concept

- Data visualization (by dashboard creation)

Step 3: Monitoring and Improvement

- Continuous monitoring

- Extensive analysis report

- Recommendations under scope for process innovation

- Manual improvements

Step 4: Co-creation

- Working together with customers to solve upcoming issues, and to continuously innovate the customer’s processes.

- Develop data solutions in cooperation with customer.

- Implement AI and possible autonomous systems if applicable.

- Implement predictive improvements and prediction systems.

Read more about i-BELT Data Management Platform

Find Out What Our Customers Say

OMRON Kusatsu Factory Case Study

“Integrating advanced technologies and human on-site capabilities for improving productivity”

Cleca improves efficiency with i-BELT

“Adding data to the mix increases productivity by 8%

Retrofit solution for OMRON Automotive Electronics Italy

“Real time data monitoring ensures defect free relays”

Related Services

Safety Services

Make your machines safe and compliant. Regional support on global scale.

Robotic Services

Up-time is a critical factor for integrated robotic solutions. Our team of robotic service specialists are dedicated to make sure that you can keep your installation healthy through the whole service life.

Proof of Concept

Proof of Concept (PoC) Service helps you to outline and solve your robotics or industrial automation solution.