RX2

Save energy and maximize performance with versatile inverter

This high performance inverter offers the same usability as the previous model and delivers improved usability: more efficient, easier, and faster.

- High starting torque in open loop: 200% at 0.3 Hz, Full torque at 0 Hz in closed loop

- Sensor-less and vector closed-loop control

- Triple rating: VLD 110%/1min, LD 120%/1 min and ND 150%/1 min

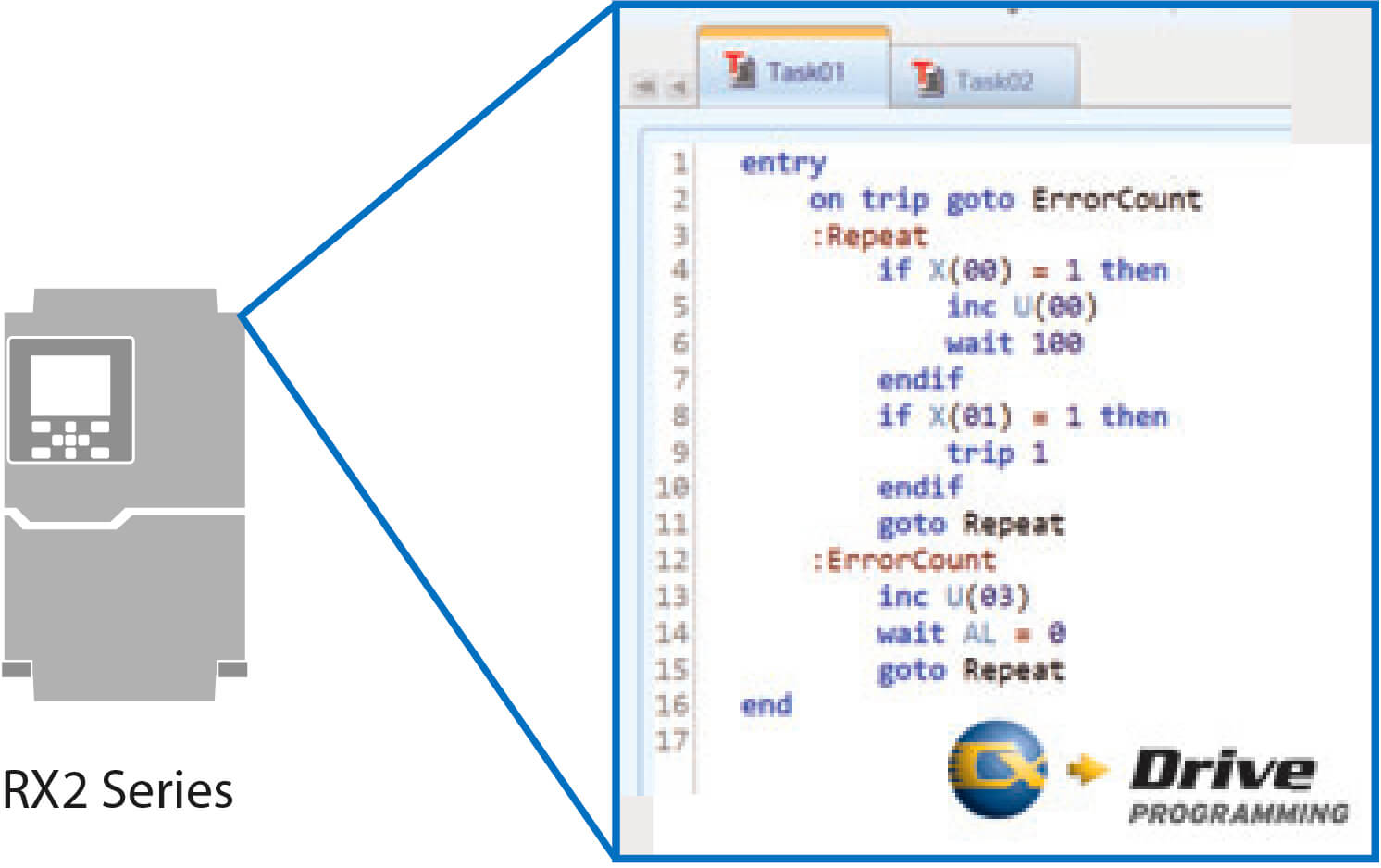

- Built-in EMC filter, logic programming and application functionality

- Positioning functionality

- Embedded STO safety function, SIL3/PLe/CAT 4

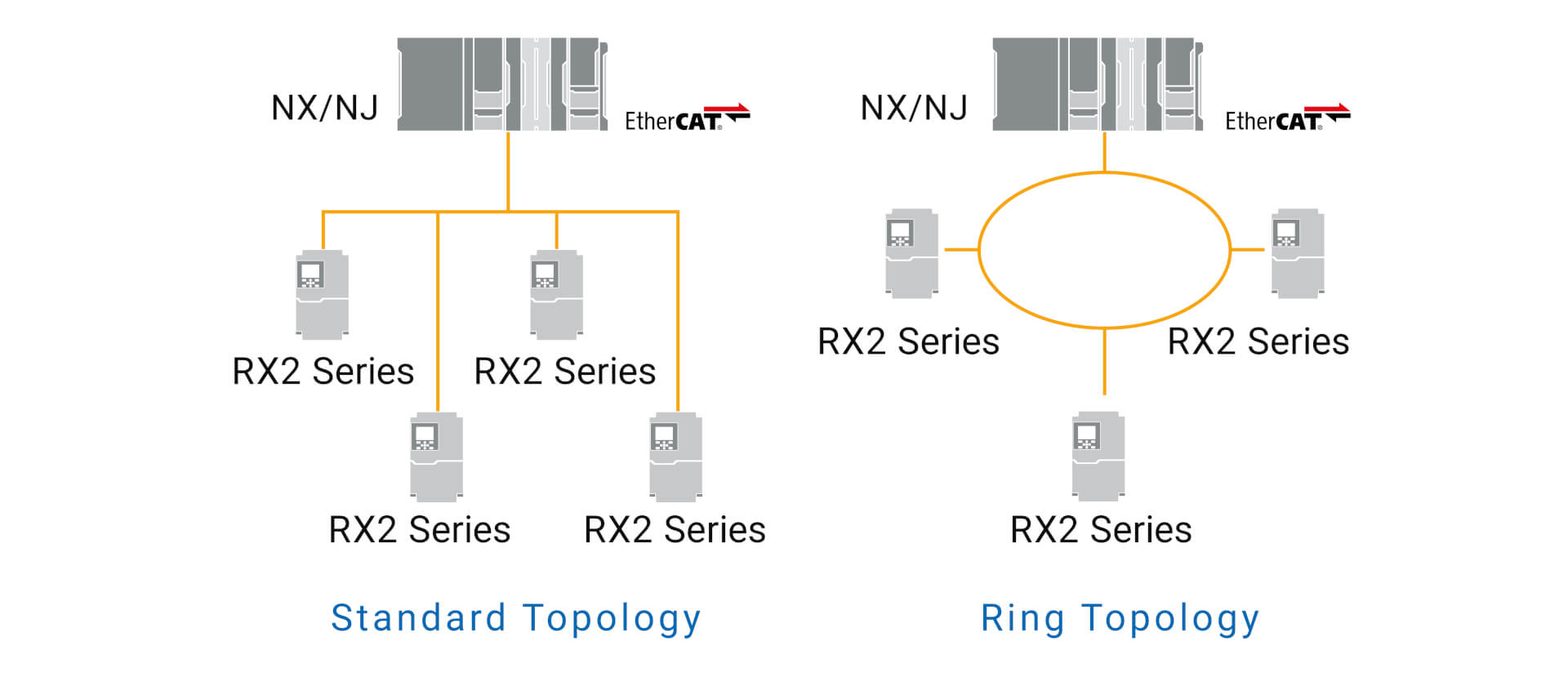

- Communication options: EtherCAT, PROFIBUS, PROFINET, Modbus TCP

- Regenerative solutions as option

- CE, CULus, RoHS

- Ratings: 200 V class three-phase 0.4 to 55 kW / 400 V three-phase 0.75 to 132 kW

Specifications & ordering info

| Product | Drive control method | Drive supply voltage | Max. motor output at constant torque | Max. motor output at variable torque | Built in EMC filter | Degree of protection (IP) | Finless type | Compatible motor type | Regenerative solutions | Communication port(s) | Communication option(s) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 0.4 kW | 0.75 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 4,4 A / 0,75 kW, LD: 3,7 A / 0,75 kW, ND: 3,2 A / 0,4 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 0.75 kW | 1.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 8,0 A / 1,5 kW, LD: 6,3 A / 1,5 kW, ND: 5,0 A / 0,75 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 1.5 kW | 2.2 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 10,4 A / 2,2 kW, LD: 9,4 A / 2,2 kW, ND: 8,0 A / 1,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 2.2 kW | 3.7 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 15,6 A / 3,7 kW, LD: 12 A / 3,7 kW, ND: 11 A / 2,2 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 3.7 kW | 5.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 22,8 A / 5,5 kW, LD: 19,6 A / 5,5 kW, ND: 17,5 A / 3,7 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 5.5 kW | 7.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 33 A / 7,5 kW, LD: 30 A / 7,5 kW, ND: 25 A / 5,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 7.5 kW | 11 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 46 A / 11 kW, LD: 40 A / 11 kW, ND: 32 A / 7,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 11 kW | 15 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 60 A / 15 kW, LD: 56 A / 15 kW, ND: 46 A / 11 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 15 kW | 18.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 80 A / 18,5 kW, LD: 73 A / 18,5 kW, ND: 64 A / 15 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 18.5 kW | 22 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 93 A / 22 kW, LD: 85 A / 22 kW, ND: 76 A / 18,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 22 kW | 30 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 124 A / 30 kW, LD: 113 A / 30 kW, ND: 95 A / 22 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 30 kW | 37 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 153 A / 37 kW, LD: 140 A / 37 kW, ND: 122 A / 30 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 37 kW | 45 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 185 A / 45 kW, LD: 169 A / 45 kW, ND: 146 A / 37 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 45 kW | 55 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 229 A / 55 kW, LD: 210 A / 55 kW, ND: 182 A / 45 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 230 V three phase | 55 kW | 75 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 200 V, VLD: 295 A / 75 kW, LD: 270 A / 75 kW, ND: 220 A / 55 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 400 V three phase | 0.75 kW | 1.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 400 V, VLD: 4,1 A / 1,5 kW, LD: 3,1 A / 1,5 kW, ND: 2,5 A / 0,75 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 400 V three phase | 1.5 kW | 2.2 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 400 V, VLD: 5,4 A / 2,2 kW, LD: 4,8 A / 2,2 kW, ND: 4,0 A / 1,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 400 V three phase | 2.2 kW | 3.7 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 400 V, VLD: 8,3 A / 3,7 kW, LD: 6,7 A / 3,7 kW, ND: 5,5 A / 2,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 400 V three phase | 3.7 kW | 5.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 400 V, VLD: 12,6 A / 5,5 kW, LD: 11,1 A / 5,5 kW, ND: 9,2 A / 3,7 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector | 400 V three phase | 5.5 kW | 7.5 kW | Yes | IP20 | No | Induction or asynchronous motor, Permanent magnet motor | As inverter option | Serial RS-485, USB | MODBUS/TCP, PROFIBUS DP Slave, PROFINET Slave | Inverter RX2, 400 V, VLD: 17,5 A / 7,5 kW, LD: 16 A / 7,5 kW, ND: 14,8 A / 5,5 kW, open/closed loop vector, built-in filter, max. output freq. 590Hz, IP20. |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts RX2

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for RX2

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Application customized

PM Motor Control

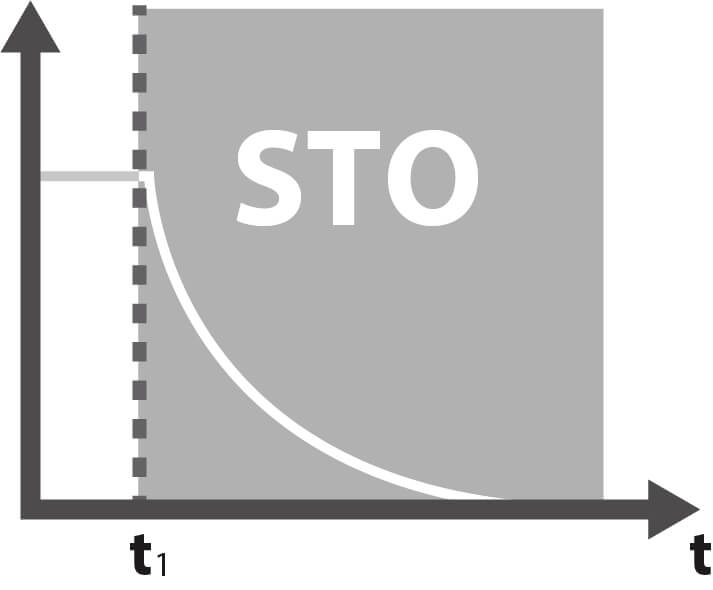

Safety embedded

The RX2 Series features Safe Torque Off (STO) as a standard, to meet your machine safety needs.

Certified standards: IEC 61800-5-2:2016 STO SIL3 ISO 13849-1:2015 Cat.4 PLe