Specifications & ordering info

Ordering information

Industrial Box PC

| Appearance | Specifications | Number of axes | Operating system | Order code |

|---|---|---|---|---|

|

Celeron 3965U fanless processor 8 GB DRAM (non-ECC) SSD iMLC 128 GB |

64 | Linux | NYB2C-31PK1 |

Industrial monitor

| Appearance | Specifications | Order code |

|---|---|---|

|

18.5-inches display with capacitive touchscreen | NYM19W-C1000 |

| 15.4-inches display with capacitive touchscreen | NYM15W-C1000 | |

| 12.1-inches display with capacitive touchscreen | NYM12W-C1000 |

Accessories

| Type | Specifications | Order code |

|---|---|---|

| Mounting brackets | Book mount | NY000-AB00 |

| Wall mount | NY000-AB01 | |

| SD memory card | 2 GB | HMC-SD291 |

| 4 GB | HMC-SD491 | |

| USB memory | 2 GB | FZ-MEM2G |

| 8 GB | FZ-MEM8G | |

| Storage devices | HDD 320 GB | NY000-AH00 |

| SSD 32 GB (SLC) | NY000-AS00 | |

| SSD 64 GB (SLC) | NY000-AS01 | |

| SSD 128 GB (iMLC) | NY000-AS02 | |

| DVI cable | Length: 2 m | NY000-AC00 2M |

| Length: 5 m | NY000-AC00 5M | |

| USB A to USB B cable | Length: 2 m | FH-VUAB 2M |

| Length: 5 m | FH-VUAB 5M | |

| Power supply | Output voltage: 24 VDC | S8VK-G |

| UPS | Output voltage during backup operation: 24 VDC ±5% | S8BA

2

Revision

number 04 or higher is required. |

| UPS communication cable | Signals for signal output (BL, TR, BU, WB), remote ON/OFF input, UPS stop signal input (BS) Length: 2 m |

S8BW-C02 |

Spare parts (included with the Industrial Box PC)

| Type | Specifications | Order code |

|---|---|---|

| Battery | Service life: 5 years at 25ºC | CJ1W-BAT01 |

| Fan unit | Service life: 70,000 hours of continuous operation at 40ºC with 15 to 65% relative humidity | NY000-AF00 |

| Accessory kit | Power connector, I/O connector, drive bracket and 4 mounting screws for drive installation, PCIe card support and clip for PCIe card installation | NY000-AK00 |

Computer software

| Item | Description |

|---|---|

| Power PMAC IDE

2

Power PMAC IDE version 2.2

or higher is needed. |

This computer software is used to configure the controller, create user programs and debug programs. This is a free software, contact your OMRON representative for information on how to procure. |

| Power PMAC-NC16 SDK | This computer software is used to control working machines and other CNC machines with the controller. Use this software when you want to customize the HMI screen. The product contains extension source codes used for customization. This is a non-free software, contact your OMRON representative for information on how to procure. |

| Power PMAC-NC16 Runtime | This computer software is used to control working machines and other CNC machines with the controller. Use this software when you do not customize the HMI screen. This is a non-free software, contact your OMRON representative for information on how to procure. |

Included support software (pre-installed on the Industrial Box PC)

| Item | Description |

|---|---|

| Industrial PC Support Utility | The Industrial PC Support Utility is a software utility to assist in diagnosing and resolving problems of the Industrial PC. |

| Industrial PC Tray Utility | The Industrial PC Tray Utility is a software utility that provides information about the current state of the Industrial PC, its related devices and associated software. |

| Industrial PC System API | The Industrial PC System API allows programmers to create programs that can retrieve information or set an indicator status of the Industrial PC. The API makes use of the included IPC System Service to manage the hardware. |

| Industrial Monitor Utility | The Industrial Monitor Utility provides a user interface to control settings and display details of connected Industrial Monitors. |

| Industrial Monitor Brightness Utility | The Industrial Monitor Brightness Utility is a small software utility that allows you to control the brightness of the screen backlight and LEDs of all connected Industrial Monitors. |

| Industrial Monitor API | The Industrial Monitor API allows programmers to create applications that can control the hardware features and retrieve information from connected Industrial Monitors. |

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts NY PMAC

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for NY PMAC

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

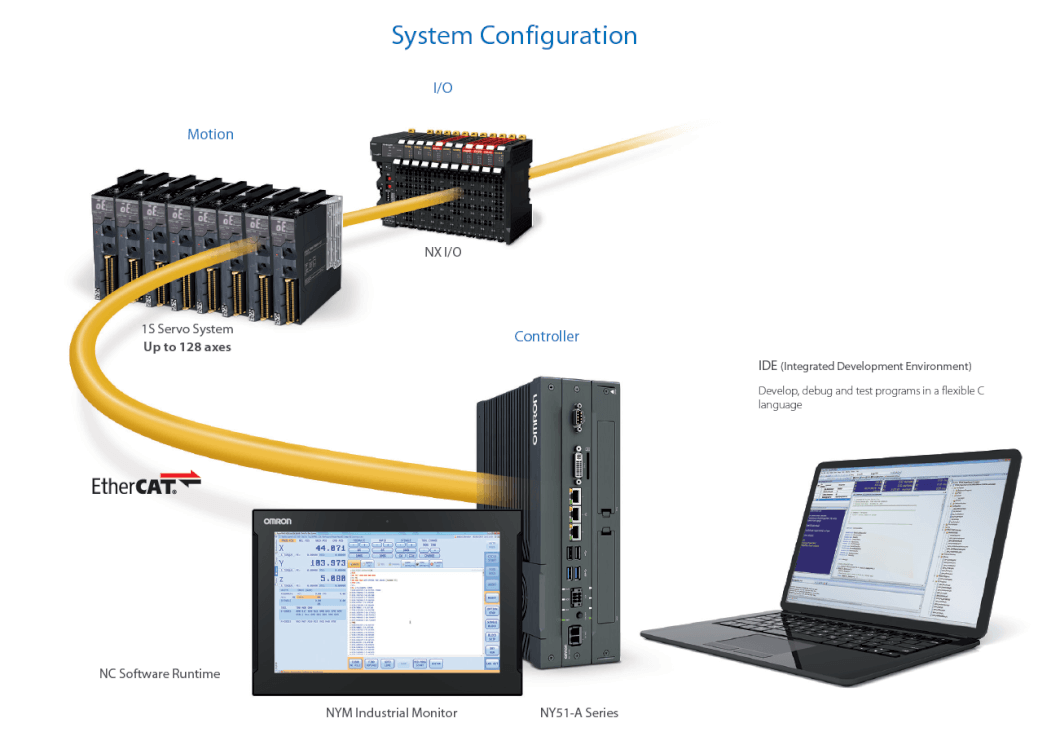

High-speed, high-precision motion controller plus PC - in one box

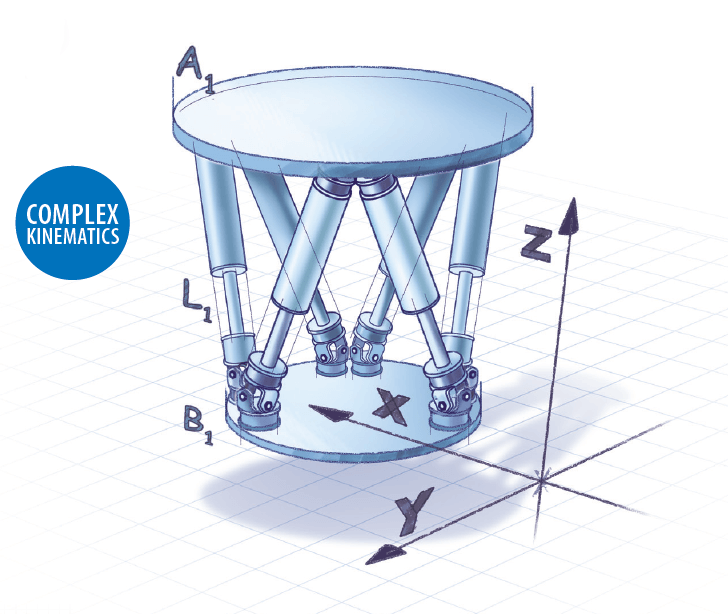

Complex kinematics

Complex mechanics can be controlled thanks to the matrix handling and the space conversion. Special applications like Hexapod telescope mirror positioning, can be easily operated by the kinematics handling functionality.

Leveraging features for accurate machining application

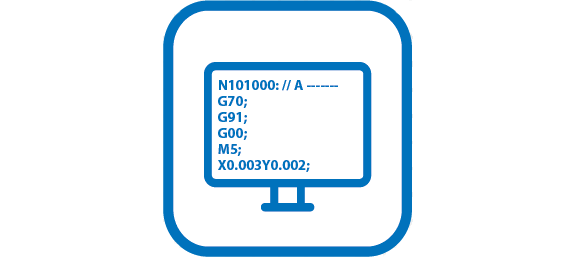

G-Code

Standard RS-274 G-Code interpreter. User-writable subroutines for customized implementation of G, M, T and D-codes. Flexibility to adapt the syntax and to work in combination with any CAD/CAM software.

Cutter compensation 2D/3D

Tool diameter and shape compensation, matching the cutting point exactly as specified in G-Code.

Fast processor + large program buffer

Fast processor can handle over 10,000 blocks per second and up to 1Gb part programs.

Block Retrace for reversing the path

Path can be reverted in order to remove the tool from cutting area.

Advanced Block Lookahead

Instructions in the buffer are analyzed in advance, movements are blended and optimized in speed and acceleration for a better performance.

Tangent tool management

Tools with a cutting direction require a tangent path positioning.

Technology

Performance

- Based on Intel® Celeron 3965U fanless processor

- 8 GB DRAM (non-ECC)

- Unique heatsink effectiveness

- RoHS Directive (2002/95/EC), EU directives

Simplicity improves reliability

Unnecessary complexity causes problems, so we’ve eliminated it totally, to improve reliability, maximize performance.

- No internal cables

- No complex heatpipes

- Structurally uniform mechanics to enable future expansion

- Reduced assembly, maintenance and labor costs

- Rock-solid architecture. Die-cast aluminum case

Software

Power PMAC IDE

This computer software is used to configure, create user programs, and debug the programs for the NY51-A, CK3E and CK3M Programmable Multi Axis Controllers.

_getting_started_guide_en.jpg)