TM S

Next generation of collaborative robots with advanced hardware options and expanded safety features

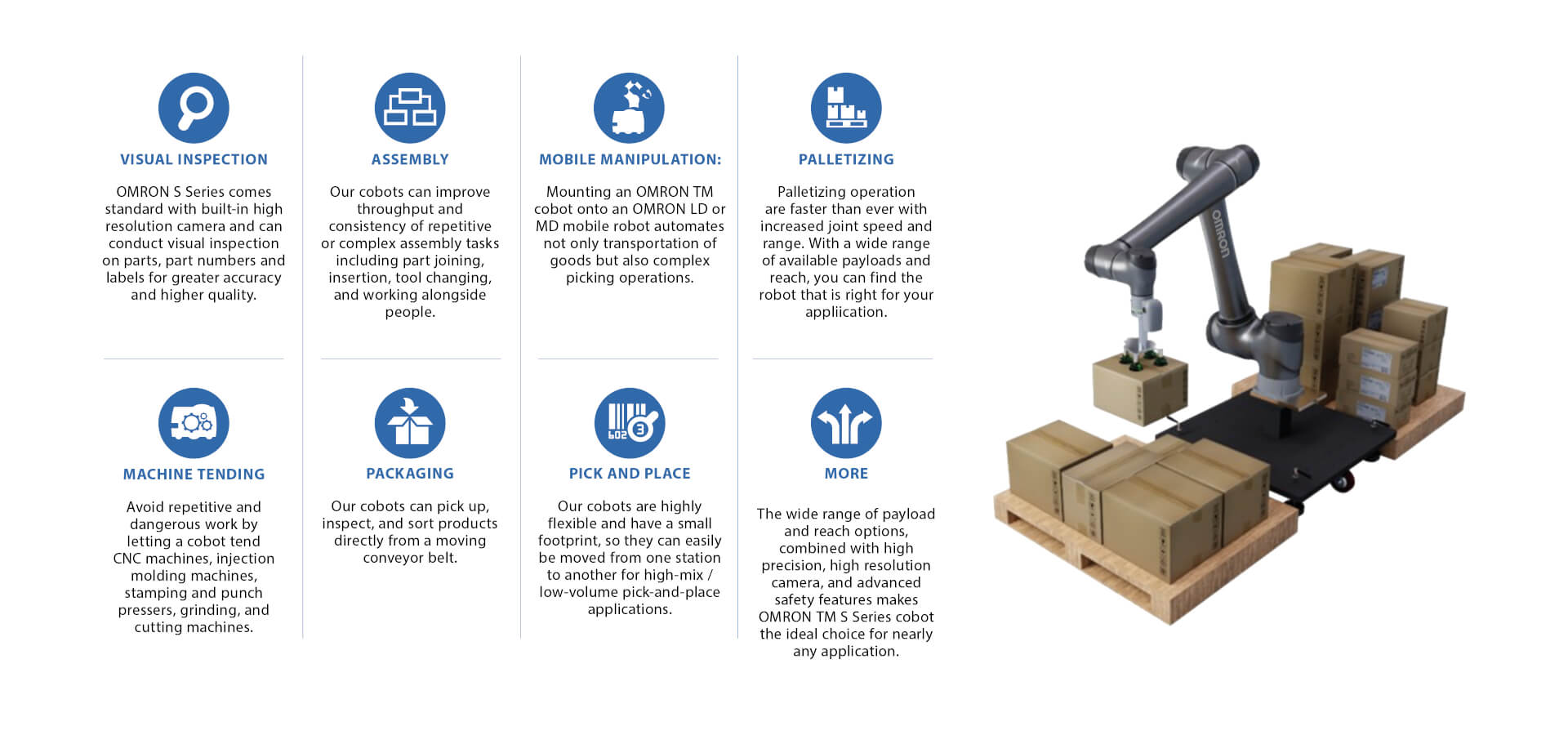

The OMRON TM S series collaborative robots are designed to increase safety of robot operations in proximity with humans and automating repetitive tasks. The next generation of OMRON cobots offer an easy-to-use programming interface, enabling engineers of all skillsets to successfully develop robotic solutions. The built-in vision system and calibration tool will relocate the cobot to different workplaces in addition to the usual vision tools for pick and place, machine tending, material handling, palletizing, and many other applications.

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011 and ISO/TS-15066

- Fast changeover using TMvision and Landmark

- Advanced collaborative control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

Features

Safety & Certification

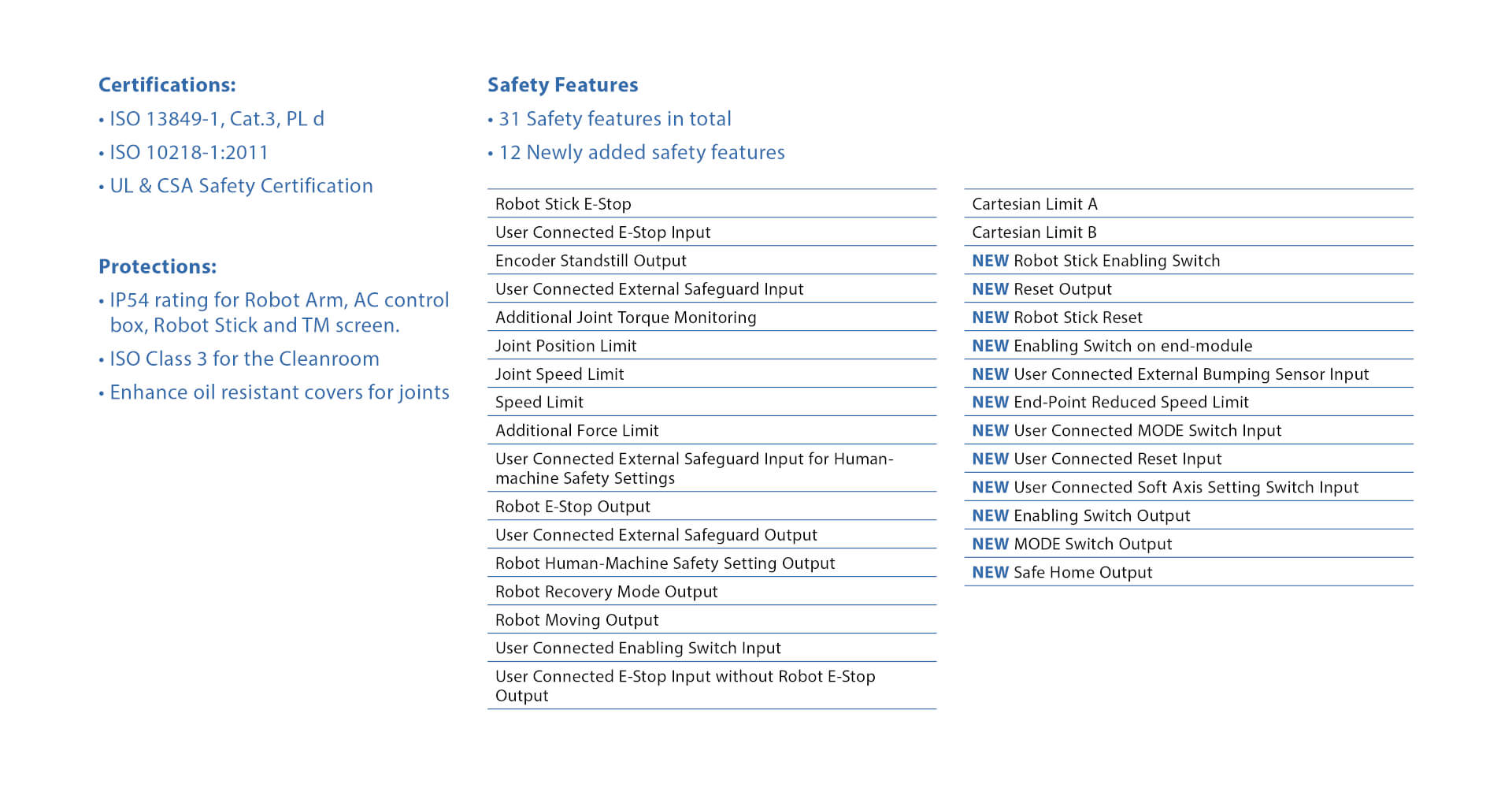

Certifications:

- ISO 13849-1, Cat.3, PL d

- ISO 10218-1:2011

- UL & CSA Safety Certification

Protections:

- IP54 rating for Robot Arm, AC control box, Robot Stick and TM screen.

- ISO Class 3 for the Cleanroom

- Enhanced oil resistant covers for joints

Easy of use – Hand Guidance

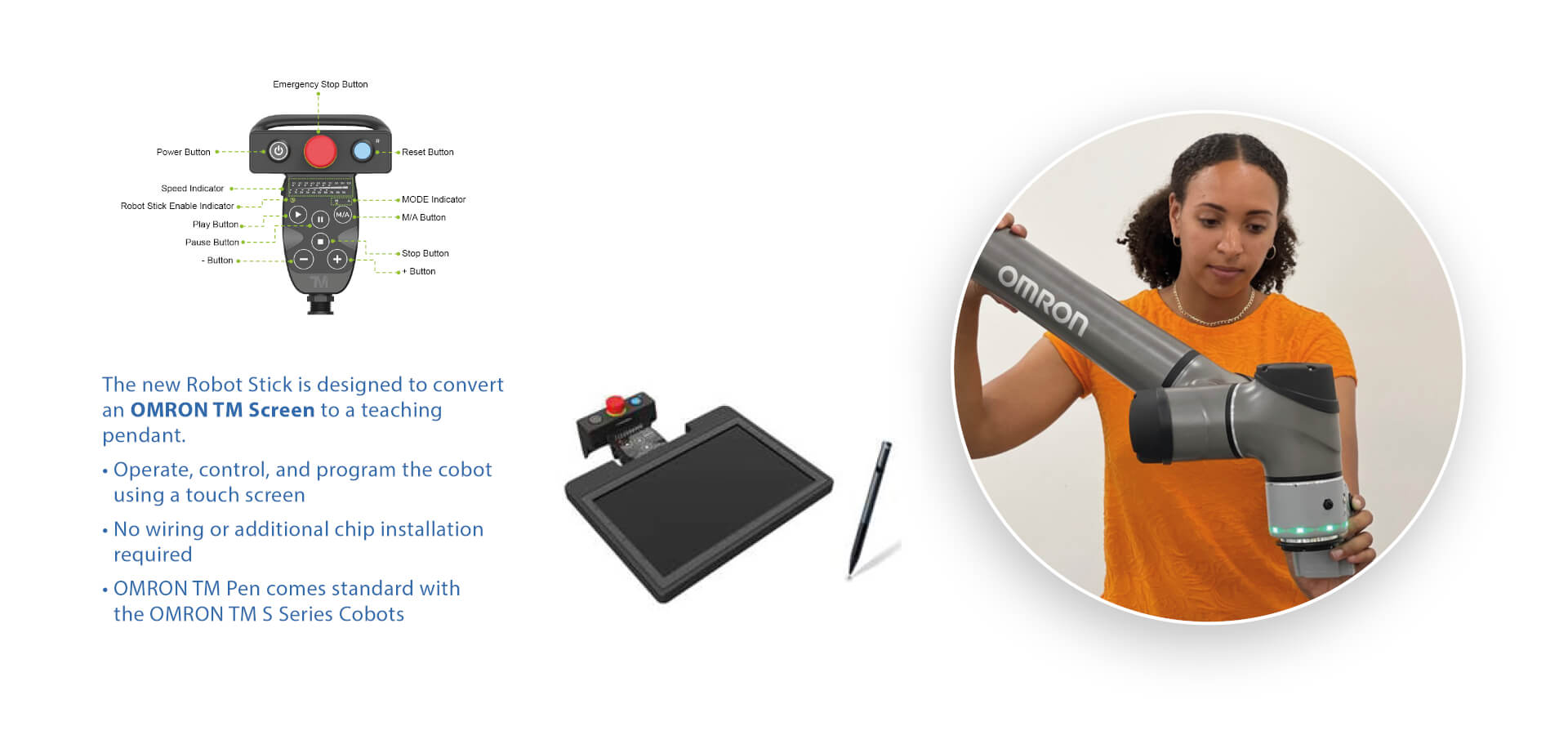

The new Robot Stick is designed to convert an OMRON TM Screen to a teaching pendant.

- Operate, control, and program the cobot using a touch screen

- No wiring or additional chip installation required

- OMRON TM Pen comes standard with the OMRON TM S Series Cobots

Easy of use - Programming

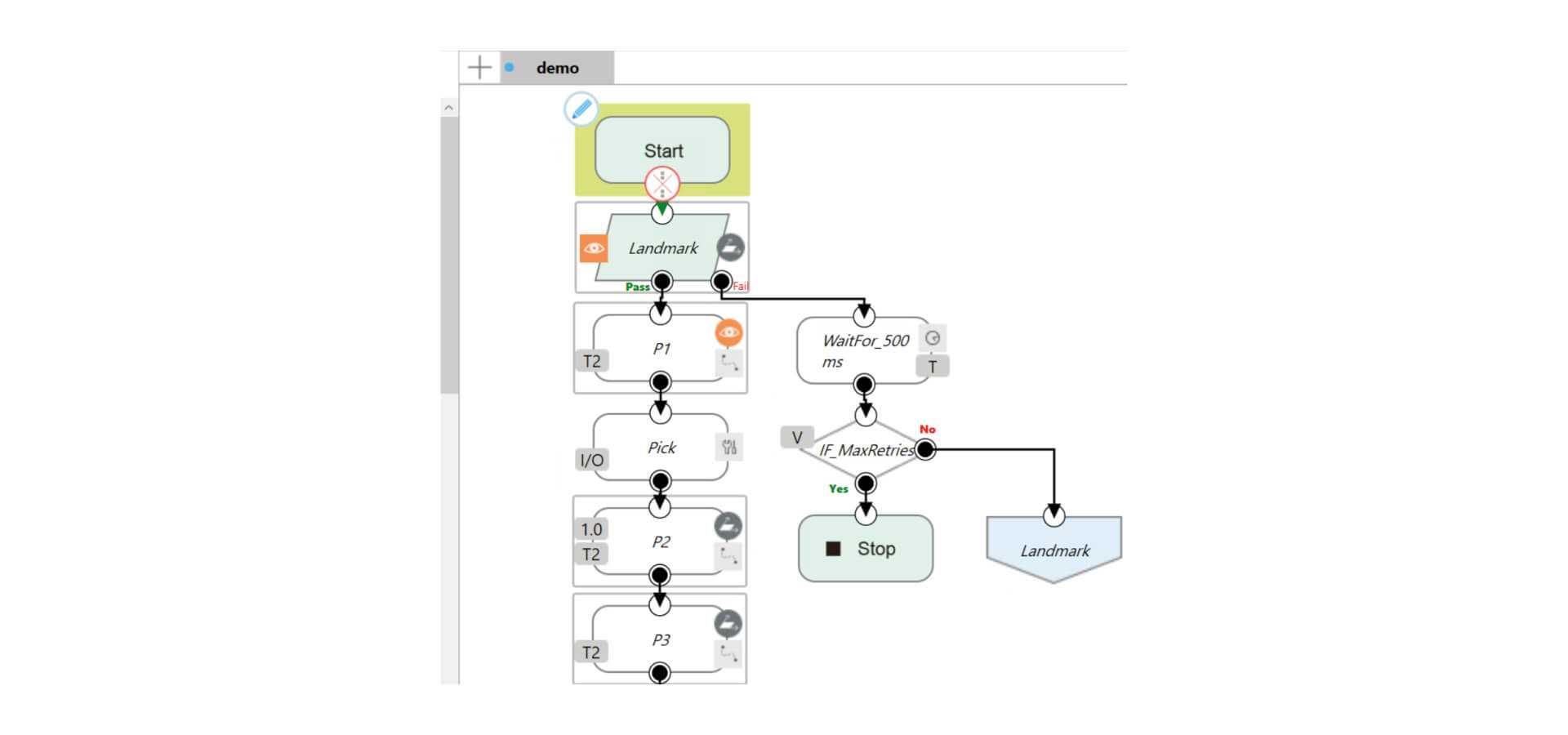

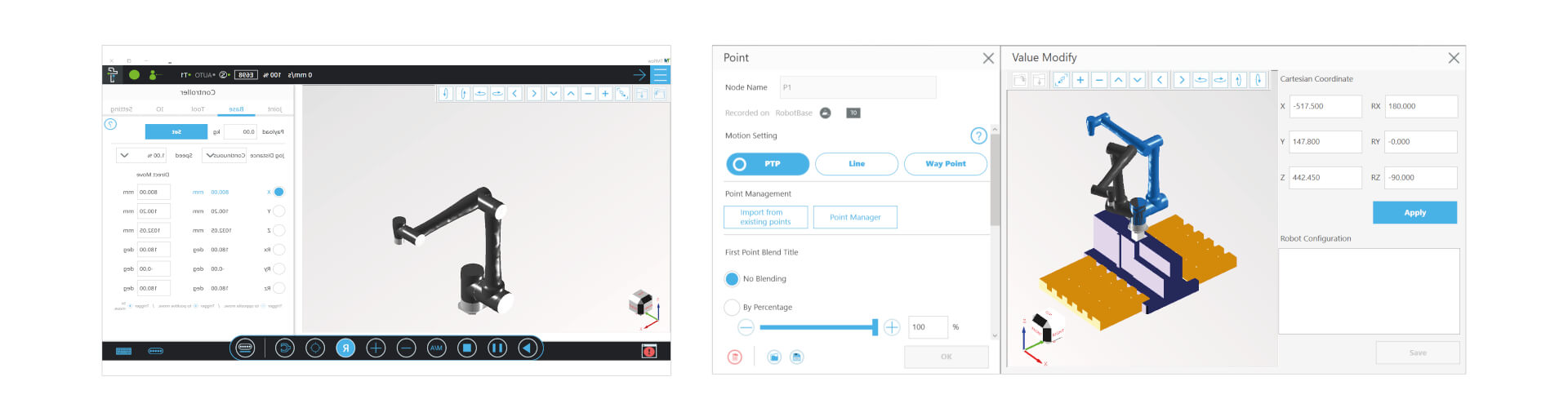

Graphical Programming

Our innovative programming allows users to automate a task with flowbased software, creating full workflows with a click-and-drag method in TMFlow. Via Operator Platform, building an application software layout is very intuitive by drag and drop visual elements, no need for trial and error via complex coding.

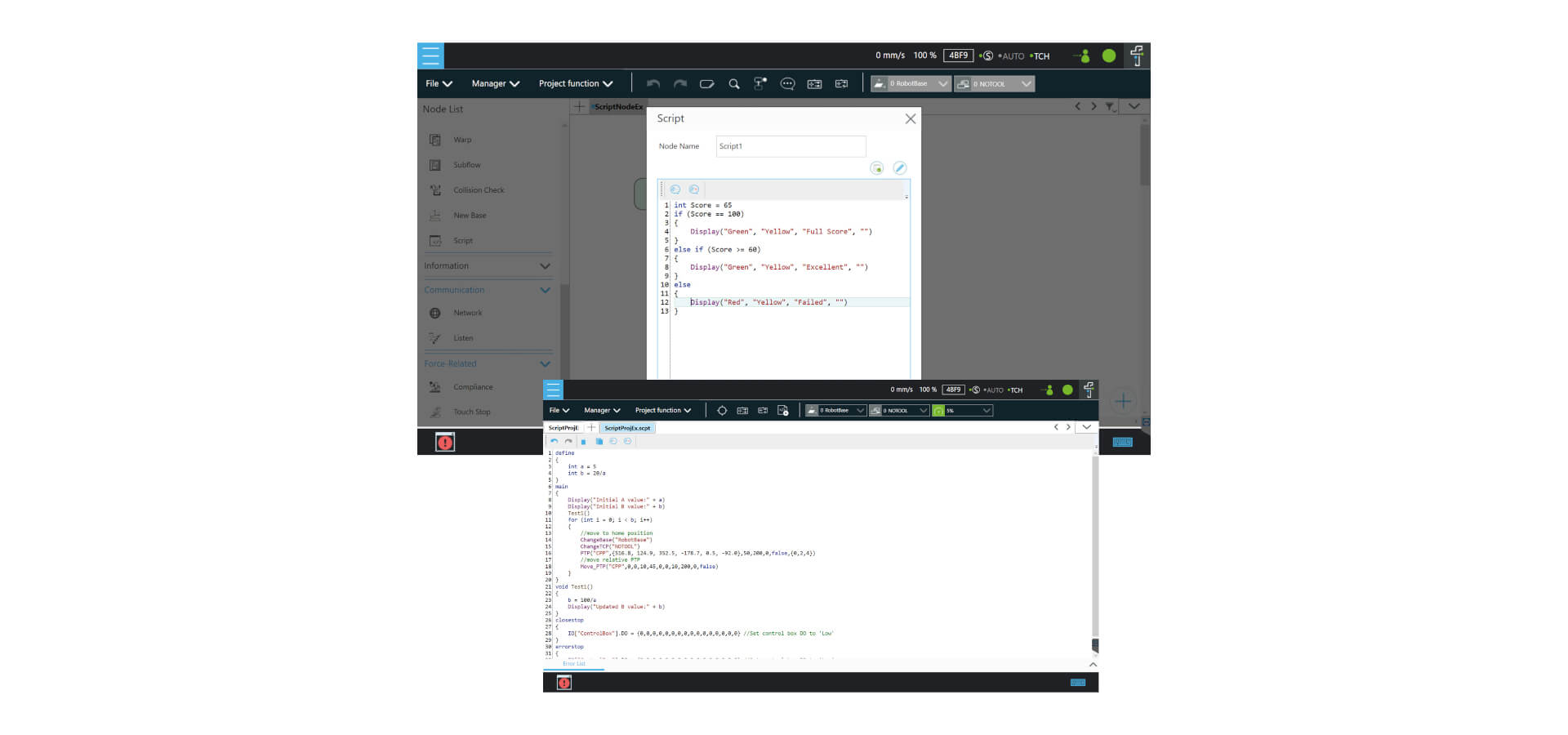

Omron Next Generation Cobot – Script Programming

The script programming method in both Project and Mode, will be available for S. The Script language may enable the advanced users to program Cobot projects more concise and organized.

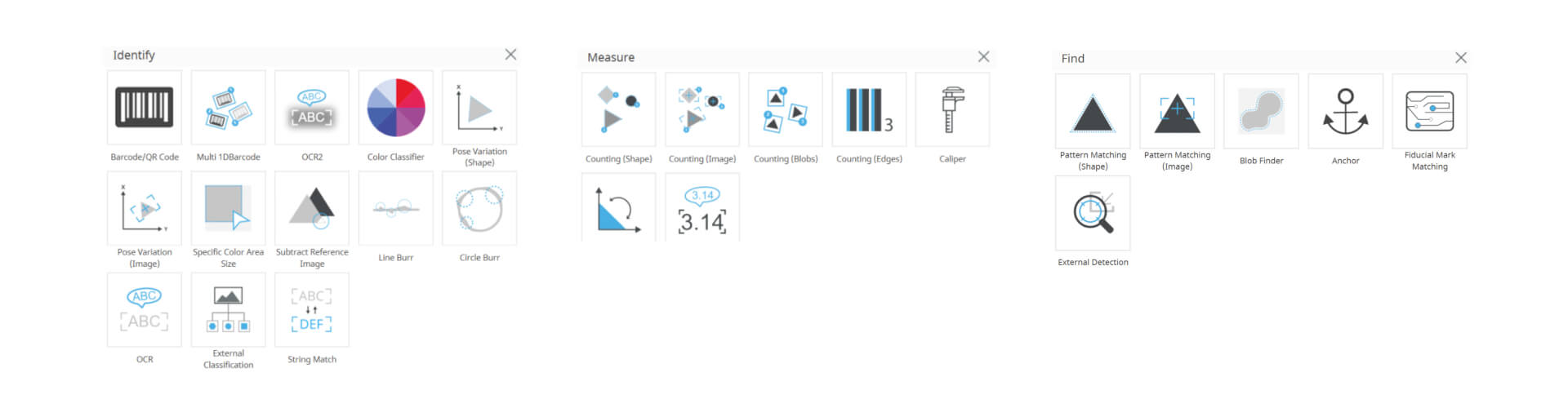

Built-In Vision System

TMSimulator

The new OMRON TMSimulator lets users test and verify proper operation by developing, editing and running programs offline. By building programs offline, users can develop new processes without having to take a robot out of production.

The onscreen display includes a virtual robot stick so users can control the robot just as they would control a physical robot. In addition to the standard robot control buttons, the virtual robot stick has buttons for RESET, Point, and Gripper.

The TMSimulator can test Listen Node and Network Node communications. Modbus, Ethernet Slave, and serial configurations can also be tested.

Target

Models

Models

TM5S

- Reach (mm): 900

- Maximum payload (kg): 5

- Maximum speed (m/s): 1.4

TM7S

- Reach (mm): 700

- Maximum payload (kg): 7

- Maximum speed (m/s): 1.1

TM12S

- Reach (mm): 1300

- Maximum payload (kg): 12

- Maximum speed (m/s): 1.3

TM14S

- Reach (mm): 1100

- Maximum payload (kg): 14

- Maximum speed (m/s): 1.1

TM25S

- Reach (mm): 1902

- Maximum payload (kg): 25

- Maximum speed (m/s): 2.1

Specifications & ordering info

| Product | Hardware version | Payload | Reach | PROFINET communication | EtherNet/IP communication | Vision | Power supply type | SEMI S2 certified | Food grade grease | SIL according to IEC 61508 | Performance level according to EN ISO 13849-1 | Cable length | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

5.0 | 5 kg | 900 mm | No | No | Yes | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | No | No | Yes | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM5S, 12 m cable, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM5S, 12 m cable, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | No | No | No | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-X (model without camera), HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | No | No | No | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM5S-X (model without camera), 12 m cable, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | No | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-X (model without camera), HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | No | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM5S-X (model without camera), 12 m cable, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | No | No | Yes | DC | No | No | 3 | Level d | 1.5 m | Bundle, Cobot, TM5S-M, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | No | No | Yes | DC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-M, 3 m cable, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | Yes | DC | No | No | 3 | Level d | 1.5 m | Bundle, Cobot, TM5S-M, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | Yes | DC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-M, 3 m cable, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | No | No | No | DC | No | No | 3 | Level d | 1.5 m | Bundle, Cobot, TM5S-MX (model without camera), HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | No | No | No | DC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-MX (model without camera), 3 m cable, HW5.0 |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | No | DC | No | No | 3 | Level d | 1.5 m | Bundle, Cobot, TM5S-MX (model without camera), HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 5 kg | 900 mm | Yes | Yes | No | DC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM5S-MX (model without camera), 3 m cable, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 12 kg | 1300 mm | No | No | Yes | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM12S, HW5.0 |

|

|

|

5.0 | 12 kg | 1300 mm | No | No | Yes | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM12S, 12 m cable, HW5.0 |

|

|

|

5.0 | 12 kg | 1300 mm | Yes | Yes | Yes | AC | No | No | 3 | Level d | 3 m | Bundle, Cobot, TM12S, HW5.0, PROFINET & EtherNet/IP |

|

|

|

5.0 | 12 kg | 1300 mm | Yes | Yes | Yes | AC | No | No | 3 | Level d | 12 m | Bundle, Cobot, TM12S, 12 m cable, HW5.0, PROFINET & EtherNet/IP |

|

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Contact Our Experts TM S

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for TM S

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download