Autonomous Mobile Robots (AMR)

How can fully autonomous mobile robots help transform manufacturing, warehouse automation and intralogistics to facilitate flexible manufacturing?

-

LD-series

Fully Autonomous Mobile Robots

-

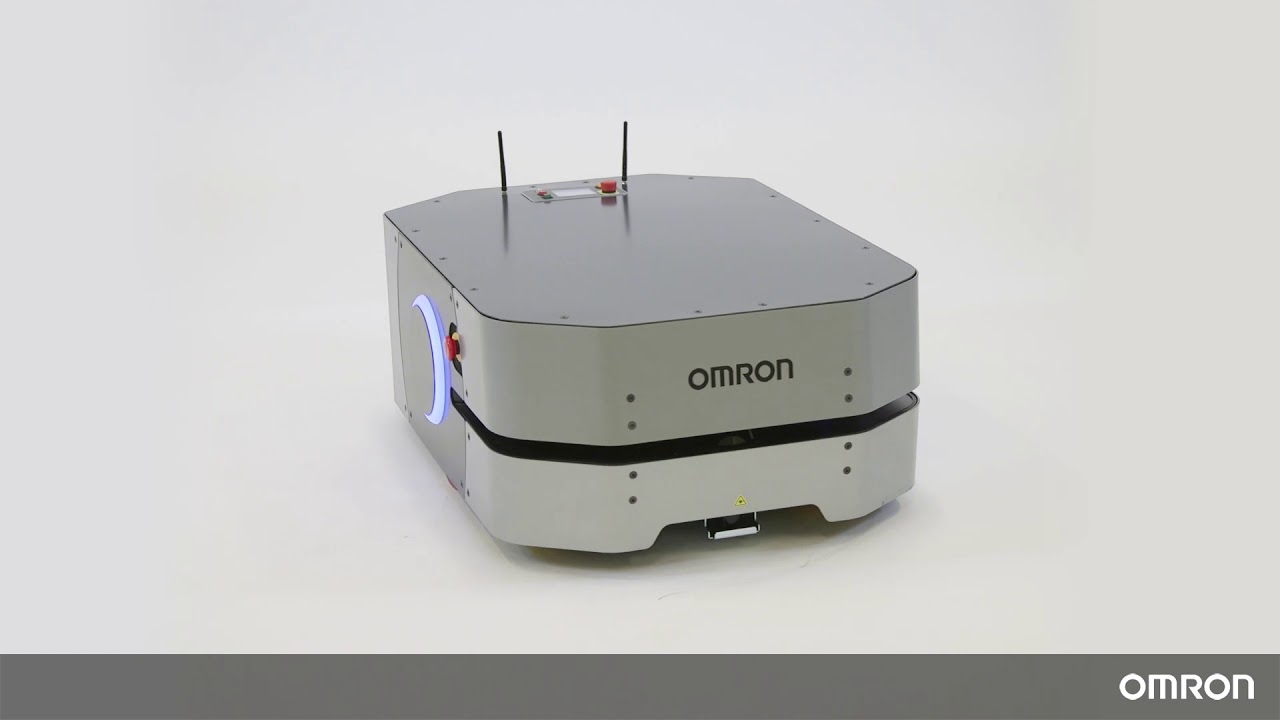

MD-series

Powerful mid-sized mobile robot with cutting-edge performance and safety

-

HD-series

Our strongest Fully Autonomous Mobile Robot

-

OL-series

Versatile and efficient mobile robot designed to streamline cart transport operations with cutting edge safety technology and performance

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts Autonomous Mobile Robot

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Autonomous Mobile Robot

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadTechnology

What are Autonomous Mobile Robots (AMR)?

AMR stands for autonomous mobile robot. These agile mobile robots are equipped with sophisticated cameras, radars and sensors, and are guided by artificial intelligence algorithms to navigate the ideal route, using the natural features of the facility or building. Autonomous mobile robots from OMRON are easy to get up and running, requiring no construction, no installation of magnets and minimal programming.

What are AMRs used for?

AMRs can also be used as service robots, for deliveries or in customer service tasks.

You might even hear them say ‘Excuse me, could I pass here’ as they can be programmed to use sounds or voice messages to alert people in their environment.

Many users name their robots and see them as part of the team, working safely together with humans and relieving them from manually moving heavy goods around and walking for miles during each shift.

The top 5 applications for AMRs in manufacturing logistics are:

- Line-side delivery

- Pick-up and delivery of work-in-progress and final products

- Order picking

- Moving pallets to and from the warehouse

- Removal of waste

AMR vs. AGV

Autonomous Mobile Robots (AMRs) on the other hand navigate freely using the natural features of the facilities. AMRs can also bring value in long distance applications if multiple input and output locations are needed, an especially if it’s important to make changes during transportation, for example call the mobile robot to carry out an urgent task. In short, AMRs are the ideal solution for last-meters delivery where flexibility is needed.

Difference between AMR and AGV

Autonomous Mobile Robot (AMR)

- Navigate freely

- Select the ideal route for the task

- Prioritize urgent tasks

- Flexible operation within a fleet

- Operate like a taxi

Automated Guided Vehicle (AGV)

- Move on fixed routes and schedules

- Use tracks for guidance

- Part of a fixed fleet

- Operate like a train

AMR Technology and Software

OMRON's Autonomous Mobile Robots (AMRs) are equipped with dedicated AMR technology for navigation and alignment positioning. This technology allows the AMRs to move safely and efficiently within their designated workspaces, even in complex environments. The AMRs are also operated by software, which makes them easy to use and program.

- The dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

Major benefits

Benefits of an Autonomous Mobile Robot

Autonomous mobile robots are ideal colleagues in your warehouse automation and optimizing intralogistics on the factory floor. Here are some of the benefits they bring.

AMRs improve safety

Free up the employees to focus on more creative tasks

AMRs improve productivity and efficiency

AMRs improve quality

Mobile Robots Intralogistics and Warehouse Automation

If material flow is not optimized, this will result in process downtime. Manufacturers also need agile solutions to scale production up and down to meet changing demand. By investing in warehouse automation automated processes with autonomous mobile robots you can ensure that materials and goods are stored and transferred correctly, simplify employee tasks, optimize workflows, improve productivity and increase capacity.

Product comparison

- Payload

- Speed

LD-series

Self-navigating Autonomous Mobile Robot (AMR) that works safely with people

The Omron LD-series Mobile Robot designed for dynamically moving material in challenging environments that may include confined passageways as well as dynamic and peopled locations.

- Payload 60/90/250 kg

- Speed 1.2 m/s - 1.8 m/s

MD-series

Powerful mid-sized mobile robot with cutting-edge performance and safety

Designed for industrial manufacturing and warehouse logistics operations, the MD-series can work collaboratively with humans and is an ideal choice for pallet-moving applications where pickup and drop-off stands can be used.

- Payload 650/900 kg

- Speed 1.8 m/s - 2.2 m/s

HD-series

The strongest OMRON's mobile robot with a heavy duty payload capacity of 1500kg

The higher payload capacity allows customers to automate new tasks that are traditionally completed with forklifts such as the transport of pallet-size loads, engine blocks, and other heavy goods and equipment.

- Payload 1500 kg

- Speed 1.8 m/s

Applications & Key Industries

-

Intralogistics process and related challenges

OMRON solution for the complete intralogistics process The complete intralogistics process in a factory is divided into four different groups because the challenges are different, but also the solutions: Lineside Replenishment; Work in progress; Finished goods and Warehouse. Read more on:

03:18

Customer Cases

-

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

03:30

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

03:32

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

-

Polar Semiconductor ensures smooth material flow with OMRON's mobile robots

Polar Semiconductor, a renowned manufacturer of semiconductor chips for the automotive and white goods industries, based at the heart of the US automotive industry, recognized the need to optimize its production processes. With the goal of reducing transportation distances within their facility and enhancing workforce efficiency to accommodate their expansion needs, Polar turned to OMRON‘s robotics technology for a flexible and cost-effective solution. Find us on: 👉LinkedIn: 👉Facebook: 👉Instagram: @omroneurope

05:08

Polar Semiconductor ensures smooth material flow with OMRON's mobile robots

Polar Semiconductor, a renowned manufacturer of semiconductor chips for the automotive and white goods industries, based at the heart of the US automotive industry, recognized the need to optimize its production processes. With the goal of reducing transportation distances within their facility and enhancing workforce efficiency to accommodate their expansion needs, Polar turned to OMRON‘s robotics technology for a flexible and cost-effective solution. Find us on: 👉LinkedIn: 👉Facebook: 👉Instagram: @omroneurope

-

UV-C robot helps businesses win the fight against Covid-19

As the UK’s customer-facing businesses plan their reopening strategies, keeping consumers and staff safe from Covid will be a key priority. In a bid to prevent future outbreaks at high footfall, everyday environments like supermarkets, bars and gyms, industrial automation specialist OMRON has teamed up with UV Systems UK, part of the Topline Group, to produce an autonomous robotic sterilisation system that guarantees to kill the virus without damage or harm to surrounding goods. The solution guarantees to eliminate viruses, pathogens and bacteria on all touchpoints within a facility, helping businesses to regain public confidence, relieve the burden on employees and meet regulations.

03:07

UV-C robot helps businesses win the fight against Covid-19

As the UK’s customer-facing businesses plan their reopening strategies, keeping consumers and staff safe from Covid will be a key priority. In a bid to prevent future outbreaks at high footfall, everyday environments like supermarkets, bars and gyms, industrial automation specialist OMRON has teamed up with UV Systems UK, part of the Topline Group, to produce an autonomous robotic sterilisation system that guarantees to kill the virus without damage or harm to surrounding goods. The solution guarantees to eliminate viruses, pathogens and bacteria on all touchpoints within a facility, helping businesses to regain public confidence, relieve the burden on employees and meet regulations.

-

Autonomous mobile robots simplify intralogistics at Diva International

Thanks to autonomous mobile robots (AMRs), the process at Diva International -an Italian producer of personal care and cleaning items, is now safer and more efficient. They have developed a new, automated system using five OMRON AMRs and OMRON’s Sysmac NJ machine controller. Large companies like Diva International are increasingly transforming their manual processes into robotics, keeping track of each step - from the order through to fulfilment in the warehouse.

04:54

Autonomous mobile robots simplify intralogistics at Diva International

Thanks to autonomous mobile robots (AMRs), the process at Diva International -an Italian producer of personal care and cleaning items, is now safer and more efficient. They have developed a new, automated system using five OMRON AMRs and OMRON’s Sysmac NJ machine controller. Large companies like Diva International are increasingly transforming their manual processes into robotics, keeping track of each step - from the order through to fulfilment in the warehouse.

-

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

02:36

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

-

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogistics

02:21

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogistics

-

Innovative production logistics at automotive manufacturer with Mini Smart Transport Robot MiniSTR

Innovative intralogistics application at the BMW Group with Mini Transport Robot, Omron LD mobile robot.

02:26

Innovative production logistics at automotive manufacturer with Mini Smart Transport Robot MiniSTR

Innovative intralogistics application at the BMW Group with Mini Transport Robot, Omron LD mobile robot.

-

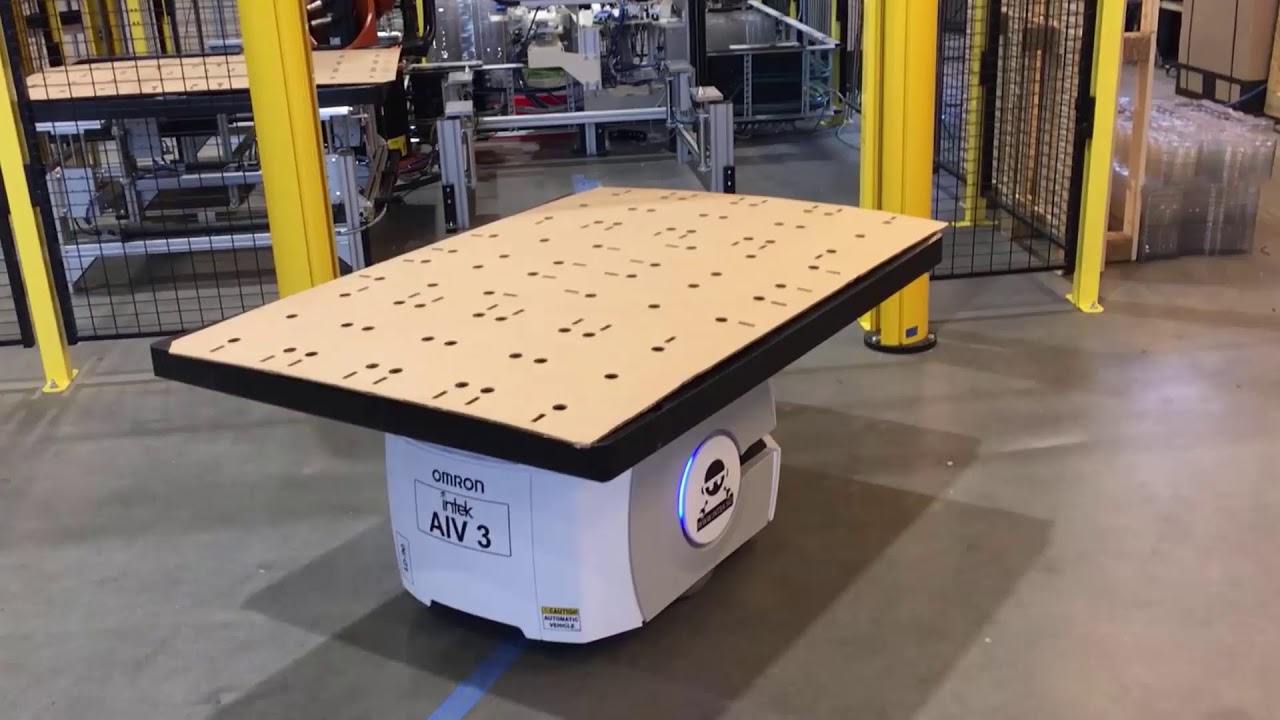

Mobile robots speed production at smart factory in Norway

Showcasing flexible production in real life, a new smart factory in Norway uses a variety of robots in a system developed and implemented by system integrator Intek Engineering. A dozen industrial robots, each in individual workstations or cells, perform different steps in the manufacturing process. Here is a demonstration from Intek Engineering on how the LD mobile robots from Omron can operate.

01:32

Mobile robots speed production at smart factory in Norway

Showcasing flexible production in real life, a new smart factory in Norway uses a variety of robots in a system developed and implemented by system integrator Intek Engineering. A dozen industrial robots, each in individual workstations or cells, perform different steps in the manufacturing process. Here is a demonstration from Intek Engineering on how the LD mobile robots from Omron can operate.

-

ŠKODA AUTO uses Omron's fully autonomous LD mobile robot at Vrchlabí plant

The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

03:00

ŠKODA AUTO uses Omron's fully autonomous LD mobile robot at Vrchlabí plant

The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

-

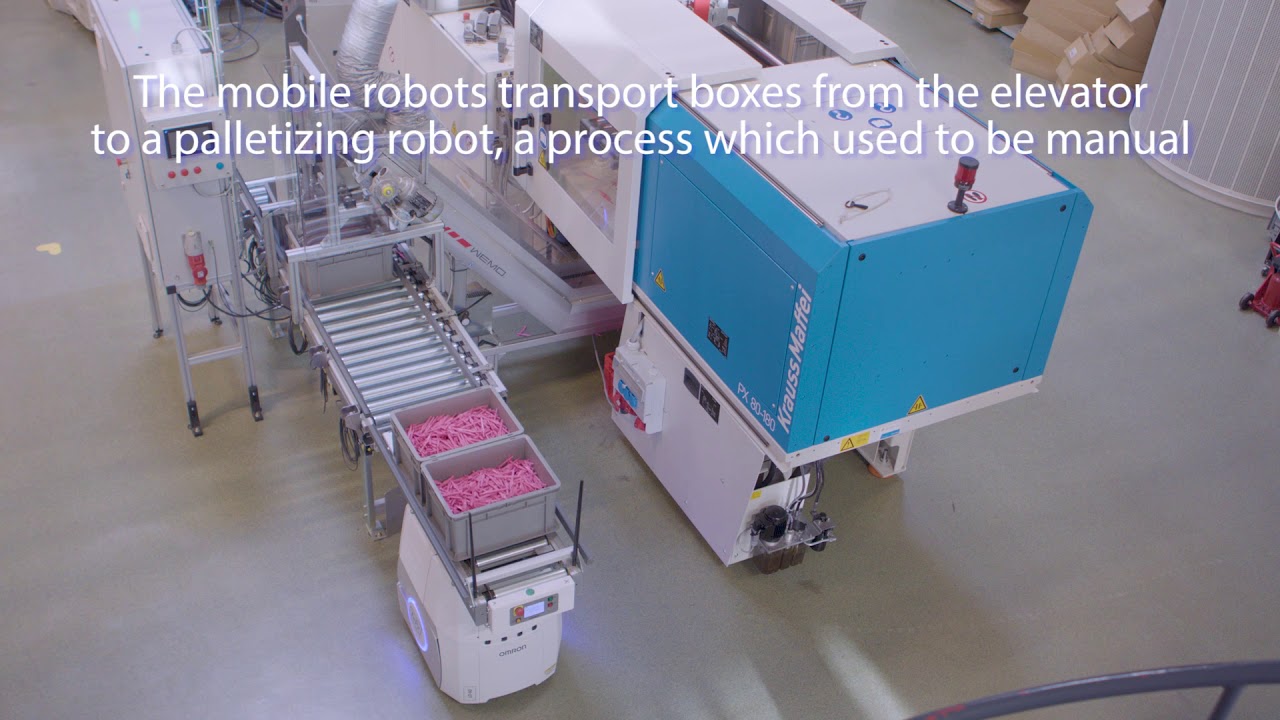

Customization and flexibility with high-speed manufacturing line and mobile robots at TePe

The oral hygiene manufacturer TePe has installed a new manufacturing line to replace its manual handling and quality inspection at their factory in Malmö, Sweden. A high-speed line from Omron comprising of industrial robots, mobile robots and vision systems now enables TePe to increase the throughput by 9 times and customise packaging for clients all over the world within seconds.

02:05

Customization and flexibility with high-speed manufacturing line and mobile robots at TePe

The oral hygiene manufacturer TePe has installed a new manufacturing line to replace its manual handling and quality inspection at their factory in Malmö, Sweden. A high-speed line from Omron comprising of industrial robots, mobile robots and vision systems now enables TePe to increase the throughput by 9 times and customise packaging for clients all over the world within seconds.

-

Mobile robot automates food distribution in a pilot at senior center

The Kustaankartano Senior Center in Finland is currently testing an autonomous mobile robot for automating food logistics between the Kustaankartano Food Centre and the senior centre. The pilot is being carried out in co-operation with Service Centre Helsinki; Helsinki Social Services and Health Care Division; and Forum Virium Helsinki. Its aim is to streamline the transport of meals to the senior centre's wards. The Polle (workhorse) robot developed by Dimalog Oy is based on OMRON’s autonomous LD-250 mobile robot. This is the strongest in the LD series of robots and can handle payloads of up to 250kg. It can navigate autonomously and is designed to interact with people to provide a collaborative and safe working environment.

03:01

Mobile robot automates food distribution in a pilot at senior center

The Kustaankartano Senior Center in Finland is currently testing an autonomous mobile robot for automating food logistics between the Kustaankartano Food Centre and the senior centre. The pilot is being carried out in co-operation with Service Centre Helsinki; Helsinki Social Services and Health Care Division; and Forum Virium Helsinki. Its aim is to streamline the transport of meals to the senior centre's wards. The Polle (workhorse) robot developed by Dimalog Oy is based on OMRON’s autonomous LD-250 mobile robot. This is the strongest in the LD series of robots and can handle payloads of up to 250kg. It can navigate autonomously and is designed to interact with people to provide a collaborative and safe working environment.

-

LD-250 autonomous mobile robot from OMRON in a pallet wrapping application

OMRON's LD-250 autonomous mobile robots (AMRs) are designed to dramatically increase productivity in manufacturing and logistics operations. They increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. And, unlike traditional AGVs, these mobile robots navigate by the natural features of the facility and require no expensive facility modification. In this video, the mobile robot, that can carry payloads of up to 250kg, is used in an automated pallet wrapping application. For more information, please visit:

02:02

LD-250 autonomous mobile robot from OMRON in a pallet wrapping application

OMRON's LD-250 autonomous mobile robots (AMRs) are designed to dramatically increase productivity in manufacturing and logistics operations. They increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. And, unlike traditional AGVs, these mobile robots navigate by the natural features of the facility and require no expensive facility modification. In this video, the mobile robot, that can carry payloads of up to 250kg, is used in an automated pallet wrapping application. For more information, please visit:Videos

-

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

01:43

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

-

Mobile robot cart transporter solution for payloads of up to 500kg

How can innovative and safe material flow contribute to creating the factory of the future? In traditional material flow processes there are many safety concern and risks, especially when operating in narrow environments, surrounded by operators. Forklifts and tugger trains are always a safety risk when working in the same area with people. How can a solution with autonomous mobile robots help ensure safety while improving efficiency and flexibility in material flow processes? The OMRON LD-250 autonomous mobile robot can be upgraded to double its usual payload from 250kg to up to 500kg by integrating into a Cart Transporter version. The user can design a custom latching system and cart based on their specific needs. The solution ensures full safety, flexibility and just-in-time delivery of goods. For more information, visit:

01:05

Mobile robot cart transporter solution for payloads of up to 500kg

How can innovative and safe material flow contribute to creating the factory of the future? In traditional material flow processes there are many safety concern and risks, especially when operating in narrow environments, surrounded by operators. Forklifts and tugger trains are always a safety risk when working in the same area with people. How can a solution with autonomous mobile robots help ensure safety while improving efficiency and flexibility in material flow processes? The OMRON LD-250 autonomous mobile robot can be upgraded to double its usual payload from 250kg to up to 500kg by integrating into a Cart Transporter version. The user can design a custom latching system and cart based on their specific needs. The solution ensures full safety, flexibility and just-in-time delivery of goods. For more information, visit:

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

-

LD-250 mobile robot tutorial 1- Getting started

In this video, you can learn how to get started with the LD-250, from unboxing the mobile robot to getting it on your wireless network, and connecting to the MobilePlanner. Get your LD-250 ready to go!

06:42

LD-250 mobile robot tutorial 1- Getting started

In this video, you can learn how to get started with the LD-250, from unboxing the mobile robot to getting it on your wireless network, and connecting to the MobilePlanner. Get your LD-250 ready to go!

LD-250 mobile robot tutorial 2 - Add the robot to your fleet

-

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

00:34

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

-

OMRON LD-60/90 Mobile Robots with Flexible Box Navigation

Introducing the OMRON LD-60/90 Mobile Robots with top conveyor for box handling. LD Top Conveyor for seamless interaction between robots, machines and humans enables production runs to be quickly and easily adjusted. MObile Robots can be equipped with tops or add-ons to carry out various tasks such as lifts to conveyors or even custom add-ons. Learn more about the OMRON LD-60/90 Mobile Robot

02:44

OMRON LD-60/90 Mobile Robots with Flexible Box Navigation

Introducing the OMRON LD-60/90 Mobile Robots with top conveyor for box handling. LD Top Conveyor for seamless interaction between robots, machines and humans enables production runs to be quickly and easily adjusted. MObile Robots can be equipped with tops or add-ons to carry out various tasks such as lifts to conveyors or even custom add-ons. Learn more about the OMRON LD-60/90 Mobile Robot

-

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

-

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

08:56

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

-

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

03:21

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobotsServices

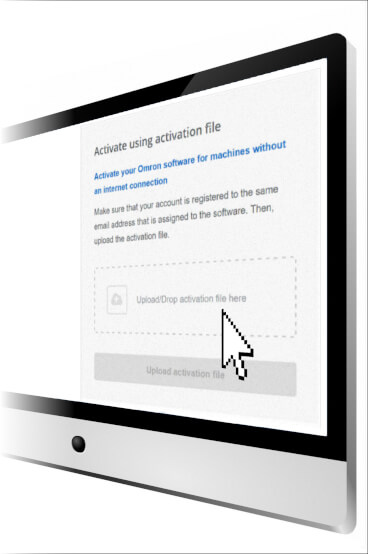

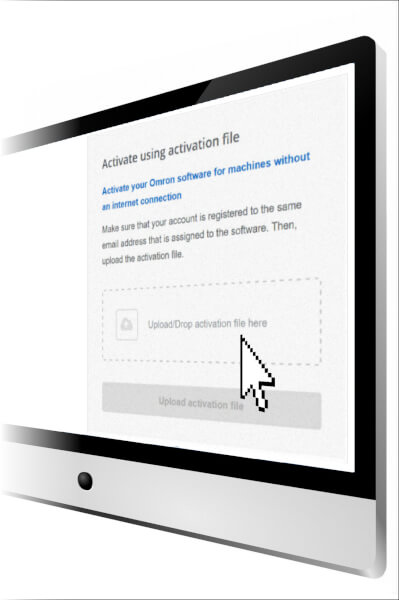

/en/misc/forms/mobile-robot-software-activation

Easily apply online to request the activation of your Mobile Robot solution licenses. Use this form to request the activation of the Mobile Robot solution licenses for any of the different devices: LD-series, MD-series, HD-series, EM2100 and Virtual Fleet Manager. Start your activation process now.

Activate your Mobile Robot Software

Easily apply online to request the activation of your Mobile Robot solution licenses. Use this form to request the activation of the Mobile Robot solution licenses for any of the different devices: LD-series, MD-series, HD-series, EM2100 and Virtual Fleet Manager. Start your activation process now.

Contact us

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Contact Our Experts Autonomous Mobile Robot

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Autonomous Mobile Robot

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download