Creating smarter, faster, and simpler multi-robot packaging lines?

Published on 16 January, 2025 in Industry 4.0

Simplify robotics in packaging with the OMRON Robotics Packaging Library

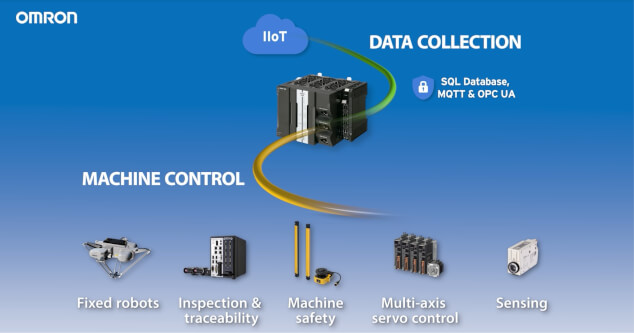

1. Full integration of robotics and automation

The Robotics Packaging Library from OMRON brings robotics and PLC control into a single system, using one controller, one software environment, and a standardized IEC programming language. This integration allows you to manage all aspects of your packaging line—robotics, motion, vision, and safety—within a single platform.

By combining everything into one system, you reduce programming time, cut down on costs, and eliminate the need for separate developers for robotics and PLC systems. Whether you're working with OMRON robotics or third-party mechanics, the library’s flexibility and compatibility ensure seamless integration.

2. Handle the unique demands of packaging lines

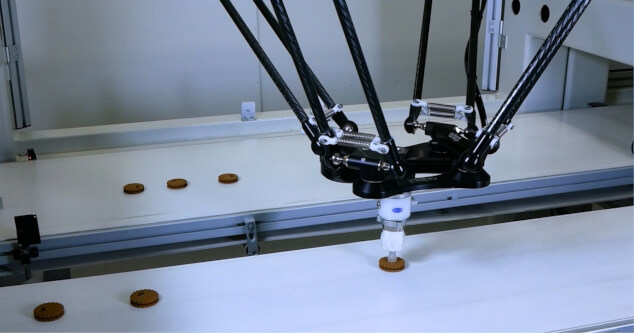

- Support for up to 16 robots: Operate multiple robots simultaneously with high performance, ensuring smooth and synchronized performance. The NX5/NX7 can support up to 16 robots, and the NJ5R up to 5 robots.

- Comprehensive kinematics support: The Robotics Packaging Library supports common and custom kinematics (up to 4 DoF) used in packaging, both when using OMRON’s robots or third-party mechanics.

- Real-time integration: The library is integrated in a system which combines vision, motion, and safety control in real time, ensuring reliability across the entire system.

3. Smooth motion and flexible transitions

- Blending for smooth transitions: Robots move seamlessly between tasks with reduced vibrations, for faster operations and shorter cycle times.

- Different motion profiles: Choose motion profiles Poly3, 5, 7 and specifying time, velocity, or acceleration to suit your specific requirements.

- Dynamic blending: Interrupt and reprogram robot movements in real time, enabling your system to adapt quickly to changes without stopping.

4. Advanced conveyor tracking

- Linear and circular tracking: Synchronize robot motions with conveyors, whether they’re straight or circular, for precise handling.

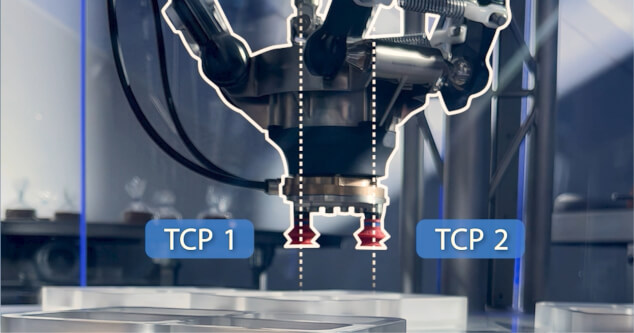

- Multi-tip functionality: Perform multiple actions on a single conveyor without stops and change movements with different Frames and TCPs in real time.

- Path Offset: Superimposed trajectories applying offsets cyclically.

Three practical benefits

- Reduced cycle times: Faster, smoother robot transitions and optimized tracking minimize delays and increase throughput.

- Simplified architecture: With one software, one control network, and one programming language, your system design is more straightforward, saving time and resources.

- Flexibility across hardware: ORPL supports OMRON robots, third-party mechanics, and custom kinematics, giving you the freedom to configure systems that suit your exact needs.

A smarter way to approach packaging robotics