Avoiding efficiency blockage: Why companies should not postpone their robotics plans?

Published on 24 September, 2024 in Operational Excellence

Delaying investments in innovative technologies is associated with numerous risks. Companies that are still hesitant should ask themselves three questions.

The European economy faces a range of challenges that impact its growth, stability, and competitiveness. Europe, for example, has one of the oldest populations in the world. An aging workforce increases the burden on social security systems and reduces the labor supply, potentially slowing economic growth. Furthermore, the EU's commitment to the Green Deal and achieving carbon neutrality by 2050 requires substantial investments and structural changes in various sectors. Added to this is a lack of willingness to invest due to financial worries. A recent study by the McKinsey Global Institute (MGI) found that large European firms with more than $1 billion in revenue have fallen behind their US counterparts. They collectively invest $400 billion a year less and grow one-third more slowly.

This investment fatigue can lead to several problems that have both short- and long-term effects, including disadvantages in terms of competitiveness, sustainability, and reputation, lower productivity, and less success in attracting new skilled workers. Innovative robotics can counteract such developments but also requires well-thought-out financing. Therefore, companies that are currently limiting their investments should urgently ask themselves whether this will not have more negative consequences for them in the long term than short-term savings. The following three questions should be the focus of such considerations:

Question 1: Why are companies that do not invest in robotics less efficient?

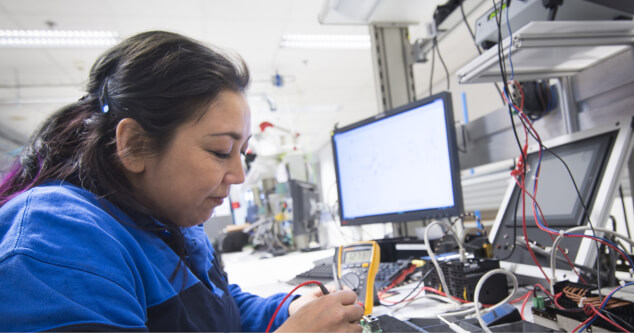

The return on investment (ROI) is traditionally used to measure the profitability of an investment. But how much does not investing in robotics hurt a company in the long run? Companies that do not invest in robotics fall behind competitors that use modern, automated systems to increase efficiency and production capacity. At the same time, they lack the innovations necessary to develop new products or services and to stay at the cutting edge of technology. Robotics can significantly increase productivity because robots can work around the clock without interruption. Companies that do not use robotics work less efficiently. In addition, automation technologies can be converted more quickly and more easily for various tasks, making them more flexible and adaptable. Without such tools, it is more difficult to respond appropriately to market changes or customer requirements. It should not be forgotten that robotics can be a means of countering the growing shortage of skilled workers in the industrial environment. For a long time, automation was seen as an alternative to workers. The tenor was that robots replace employees. Collaborative robotics, on the other hand, relies on closer cooperation between employees and machines, and human skills can be maximized through user-oriented automation. The acceleration of data-driven processes through digitization strengthens employees by, for example, using AI-based applications to support employees in making informed decisions. Options such as leasing or robot-as-a-service can be good options for acquiring new technology. OMRON provides small and medium-sized enterprises (SMEs) with an ROI calculator to help them better understand the financial aspects of automation. If you are considering purchasing or renting a cobot, this tool can show you the return on investment and when an investment will break even.

Question 2: Why are companies that do not invest in robotics less sustainable?

Many companies have made sustainability their mission and are increasingly responsible for implementing sustainable processes, keyword corporate responsibility. What is often overlooked here is the fact that automation technologies can promote social and ecological goals in a variety of ways. A key requirement is that processes and systems are optimally coordinated. Sensors and AI enable companies to detect problems that may occur in a system, such as irregularities like vibrations or malfunctions, at an early stage and to take countermeasures. Optical control and innovative camera technology help to detect errors and quality deviations at an early stage and to react before thousands of defective parts are produced, machines have to be stopped and avoidable additional costs are incurred due to rework or waste. Ideally, all machine processes are coordinated and interlinked seamlessly for the benefit of efficiency and sustainability. OMRON's machine control with an integrated robot platform, for example, helps to radically reduce changeover times for production lines. Companies are being challenged to review their working practices, create sustainable processes, and support their employees through automation.

Question 3: Why are companies that do not invest in robotics less employee-friendly?

There are some misconceptions when it comes to investing in robotics. A common fear is that robots will take away jobs from employees. However, this assumption is wrong: successful automation offers the opportunity to support employees instead of replacing them. The robot takes over repetitive tasks, but the human makes the decision. Smart technologies such as robotics, big data and cloud computing, augmented reality (AR), and the Internet of Things (IoT) can help to address the growing shortage of skilled workers by enabling added value and flexible workflows. Working with technology providers such as OMRON and its partners, who are well-versed in tools such as 5G, edge AI, or data analysis, can significantly simplify the implementation and use of such technologies. Another tip: from planning to proof of concept (POC) to a system that runs successfully and profitably, time, patience, and a trusted partner is required. Companies must ask themselves in advance which technology is best suited to their requirements and how it can be scaled. Employee acceptance also plays a major role while automating processes. It is advisable to start small, implement initial projects, and then scale quickly.

Conclusion: Focus on application needs instead of costs

Investments in new technology should not be thought of in too narrow a way. Instead, they should be seen as an investment in the future. A ROI calculation alone is not sufficient to fully outline the advantages and possibilities of innovative robotics for companies. Instead, all stakeholders should be brought on board to get a holistic picture of all concerns. For example, it is not advisable to focus on the costs of a new technology, such as a cobot, if such a tool can be used, converted, and expanded in a variety of ways and it is therefore not yet possible to determine exactly where processes can be optimized. Instead of focusing on the technology and its costs, decision-makers should think and act in a more application-oriented and holistic way. A strong partner network as that offered by OMRON helps to realize company-specific adaptations and to find a robotics solution that exactly matches your requirements.