EU GMP Annex 1, requires robust and strict quality control practices that do not disturb the line flow and gurantee the aseptic conditions of the filling and finishing process of medicinal products. Our latest innovations in quality inspection technologies address the most demanding quality control needs in the pharmaceutical and biotech industry.

Annex 1, RTU devices and multiformat lines require a high performance inspection platform

Market trends and regulation changes like multiformat lines, ready to use devices or Annex 1 requirements are demanding robust visual quality inspection to assure the quality of the product without impacting throughput and efficiency of the line, while keeping costs under control. Inspection solutions in the market are often tailored, difficult to adjust to certain use cases and complex to validate, increasing costs and implementing time.

OMRON FH machine vision inspection platform with offline simulator and optional EDGE AI

OMRON machine vision system can perform the most complex inspections, all on a single platform. Enabled with high-precision vision inspection algorithms, FDA CFR21 part 11 compliant mode software, offline simulator and hygienically designed hardware and accesories, our advanced FH inspection system platform provides manufacturing sites with a unique solution to enable the next level in quality control at all stages of the aseptic filling process.

A single machine vision inspection platform for various applications

Whether it be vials, syringes, or cartridges, OMRON has developed a comprehensive portfolio of applications - such as empty container inspection, stopper position, crimp control, particle detection or robot guidance, all compliance with FDA 21 CFR Part 11 software - tailored to the needs of your aseptic liquid filling line. All applications are in use by major customers in the market and provide support for your validation process. To cope with the Annex1 demand on new technologies, AI for classification, counting and defect becomes available and may be added.

Enabling Technologies

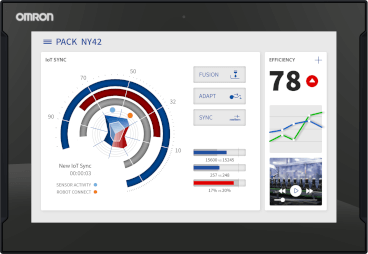

Industrial Monitor

Display and touch interface for the Industrial PC Platform.

Faster machine operation, cameras for every application

Experience Unmatched Precision and Efficiency with the Omron FH Vision System: Revolutionizing Quality Control and Automation in Manufacturing

Related Solutions

Print Quality Inspection Systems

The V275 ensure that every label meets your quality standards. It is the only barcode quality grading system for use with Zebra thermal printers that complies with ISO 15426 and GS1 standards, required for compliance to industry regulations such as FDA.

Consultation Desk Services

Receive cross-border support and expertise in your own language. Consultation Desk Service enables a quick and cost-efficient cross-border service without compromising with quality