NA series

NA Series -The Sysmac HMI

As part of the Sysmac automation platform, Omron NA HMI transforms machine data into information, shows information and controls devices based on requirements at FA manufacturing sites. The NA Series enables faster, more efficient control and monitoring. With a widescreen displaying 16,770,000 colors, the HMI that is dynamic, intuitive and predictive makes industrial machines more attractive and competitive.

- Proactive operator/ machine relationship

- Design based on real applications and customer requirements

- Future-proof, scalable platform

- Allows quick reaction

- 16,777,000 display colors (24 bit full colors)

- High resolution display

- 1,280x800 resolution for 12-inch and 15-inch models

- 800x480 resolution for 7-inch and 9-inch models

Specifications & ordering info

| Product | Screen diagonal | Frame color | Type of display | Number of Ethernet ports | Number of USB ports | Number of RS-232 ports | Number of colors of the display | Number of pixels, horizontal | Number of pixels, vertical | Degree of protection (IP), front side | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

12.1 in | Black | TFT | 2 | 3 | 1 | 16777216 | 1280 | 800 | IP65 | Touch screen HMI, 12.1 inch wide screen, TFT LCD, 24bit color, 1280x800 resolution, frame color : Black |

|

|

|

12.1 in | Silver | TFT | 2 | 3 | 1 | 16777216 | 1280 | 800 | IP65 | Touch screen HMI, 12.1 inch wide screen, TFT LCD, 24bit color, 1280x800 resolution, frame color : Silver |

|

|

|

15.4 in | Black | TFT | 2 | 3 | 1 | 16777216 | 1280 | 800 | IP65 | Touch screen HMI, 15.4 inch wide screen, TFT LCD, 24bit color, 1280x800 resolution, frame color : Black |

|

|

|

15.4 in | Silver | TFT | 2 | 3 | 1 | 16777216 | 1280 | 800 | IP65 | Touch screen HMI, 15.4 inch wide screen, TFT LCD, 24bit color, 1280x800 resolution, frame color : Silver |

|

|

|

7 in | Black | TFT | 2 | 3 | 1 | 16777216 | 800 | 480 | IP65 | Touch screen HMI, 7 inch wide screen, TFT LCD, 24bit color, 800x480 resolution, frame color : Black |

|

|

|

7 in | Silver | TFT | 2 | 3 | 1 | 16777216 | 800 | 480 | IP65 | Touch screen HMI, 7 inch wide screen, TFT LCD, 24bit color, 800x480 resolution, frame color : Silver |

|

|

|

9 in | Black | TFT | 2 | 3 | 1 | 16777216 | 800 | 480 | IP65 | Touch screen HMI, 9 inch wide screen, TFT LCD, 24bit color, 800x480 resolution, frame color : Black |

|

|

|

9 in | Silver | TFT | 2 | 3 | 1 | 16777216 | 800 | 480 | IP65 | Touch screen HMI, 9 inch wide screen, TFT LCD, 24bit color, 800x480 resolution, frame color : Silver |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact Our Experts NA series

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for NA series

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Integrating your world

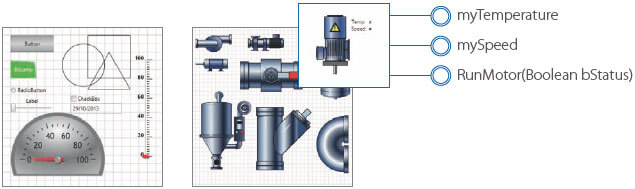

The NA Series can be programmed alongside the other devices in one integrated project, which speeds up development.

- Share NJ/NX/NY Controller Variables (Tags) in the machine interface application.

- Variables shared with controller reduce the time and complexity of programming.

- Define/use NA data structures in the machine interface application

- Work in a familiar way on all devices.

Be more productive

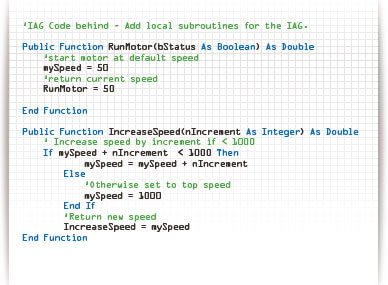

- Use NA Intelligent Application Gadgets (IAG) or create your own ones.

- Write your Visual Basic Script

- Integrated testing through simulation of programs on controller and HMI at the same time.

- Checking your device operation at the same time makes debugging quicker and easier.

- Quickly test your device operations via the Simulator.

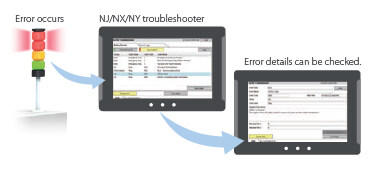

Minimize downtime: integrated troubleshooter

The Troubleshooter on the NA Series allows you to directly monitor and release the NJ/NX/NY Controller errors and events as well as the user-defined errors and events. There is no need for support software running on a PC.

Increased security

The NA Series can be configured to specific staff, with multi access levels with password protection. This ensures authorized people interact with the machine.

- Your project can be password-protected along with other applications (Control and Safety).

- Transferring data can be protected (disable overwrite or theft).

Remote access

- You can view and operate the HMI installed at production sites from your tablet using Ethernet or WiFi.

- The access of remote devices can be managed and limited. This helps prevent accidental operation and information leakage, while securing accessibility.

_users_manual_en.jpg)