Latest news

Statement on vulnerabilities in Apache Log4j: OMRON Industrial Automation products are not affected

14 January, 2022 The Apache Software Foundation has published information about a vulnerability in the Java logging framework log4j.

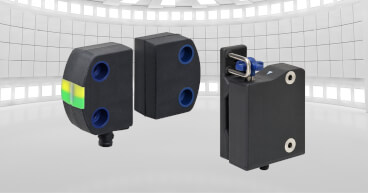

New V440-F Series ultra-compact, high-resolution, networked code reader

16 December, 2021 OMRON expands the MicroHAWK range with the V440-F, which is ideal for reading multiple codes in a wide area, as well as for applications over longer distances and with minuscule barcodes.

New RT1-Series Site Manager for Secure Remote Access

09 December, 2021 Security certified IIoT edge gateway enables remote troubleshooting and monitoring

OMRON listed in the Dow Jones Sustainability World Index

22 November, 2021 OMRON Corporation has been listed for the 5th straight year on the globally recognized Dow Jones Sustainability World Index.

OMRON awarded the Gold Rating under the PRIDE index for the 5th consecutive year

18 November, 2021 OMRON Corporate was designated as a Gold Standard Workplace, the highest evaluation under the PRIDE Index by ‘Work with Pride’.

Update from the European Repair Center – New shipping address as of the 1st of December 2021

01 November, 2021 As part of our continuous journey to improve our service level, we are creating a new EMEA Repair Center in a new facility in Den Bosch, The Netherlands.

OMRON invests in Taiwan’s collaborative robot company Techman Robot Inc.

29 October, 2021 OMRON will hold a stake of approximately 10% in Techman, offering robotic technology where humans and machines work together.

-

Experience manufacturing of the future first hand: Opening of the Automation Center in Barcelona!

In its Automation Centres, OMRON Industrial Automation opens the door to the factory of the future, where customers and OMRON engineers jointly develop ideas for innovation projects and exchange ideas in workshops and lectures. The adjoining showroom illustrates the latest developments in the field of automation. The newly updated and expanded Automation Center Barcelona is one of the 37 Automation Centres around the world, and the first in Europe. With the addition of 320m2, the facility now boasts 831m2 of floor space, and enables European customers to truly experience the benefits of having a connected, automated and intelligent factory.

01:05

OMRON opens doors to the factory of the future with updated Automation Center in Barcelona

25 October, 2021 OMRON’s first Automation Center in Europe has recently received a major redesign and now includes an extensive demonstration area for innovative automation applications.

Introducing the world’s most advanced 3D AOI system: Our new S10 Series -ultimate solution for manufacturers’ new challenge: “Unmanned inspection System”

01 September, 2021 The world of automation is in consistent movement, and it is no secret that today’s manufacturing environment is complex! Trusted for almost 90 years, we are a world leader in automation and, the global market leader in Automated Optical Inspection systems solutions during the past 35 years. We are proud of introducing our new S10 Series, the world’s 1st full colour system, offering a unique mix of general purpose and application specific solutions. S10 Series enable flexible manufacturing, respond to shortages in manpower and demands for higher quality production.

Current supply chain statement and the OMRON approach

28 July, 2021 Current supply chain statement and the OMRON approach

OMRON Variable Speed Drives and Electronic Displays go green

05 July, 2021 The European Union aims to achieve a market of sustainable, climate-neutral and resource-efficient products.

Introducing the D41 Series High-Coded Safety Door Switch

05 July, 2021 Reducing the risk of interlock devices being deactivated, for a safe and worry-free production site.

Q2V Compact Drive – Driving Quality

29 October, 2019 The Q2V combines easy operation with high-efficiency control for almost any AC motor type, reducing the need for maintenance while saving energy.

Complete renewal of the compact controller range

17 October, 2019 Two new models released in the NX1P family of compact Sysmac Machine Controllers for maximum scalability and flexibility

New CP2E Series all-in-one controller

17 October, 2019 Programmable micro PLC is designed to support data collection and machine to machine communication. Extended temperature range increases reliability in special applications.

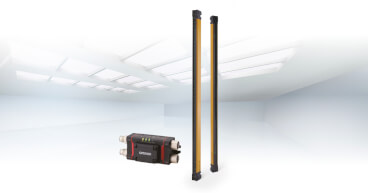

F3SG-SR series redefines safety at manufacturing sites

09 October, 2019 The F3SG-SR series offers a complete line-up of light curtains, which includes a wide variety of applications and protective heights, covering all aspects from design through to maintenance.

Easy electrical wiring design for Omron panel solutions with PCSCHEMATIC

11 September, 2019 1500 Omron components to be included in the electrical CAD software PCSCHEMATIC Automation.

-

Component Focus: Omron Wireless Buttons

I'm Josh Bishop for cooling. It takes a wide voltage input from 100 to 240 volts AC and accepts either 50 or 60 Hertz. You can connect the incoming power here at the bottom with line, neutral and ground inputs. This particular power supply outputs the 24 volt DC power at the top with these terminal blocks and can provide up to 15 watts which is ample power for this wireless receiver or many other devices. There are other S8V caged power supplies that can output more power, but this works great in this case. The S8VK is providing power to this wireless receiver the A2W-RPC- WC1. This receiver is very straightforward to use with clearly marked ports and switches and common sense usage. This has eight outputs and accordingly can be synced with eight wireless buttons. You can see the power input up at the top and the outputs here at the bottom. There are lights for power, any potential errors and receipt of signals right here. There's also a slide switch for usage testing and setup. You'll note that this is 922.5 megahertz which gives it a greater range and better signal propagation than higher frequency signals. We end up with the communication assistance of about 100 meters without any obstructions. Finally we have the two push-button switches. They're obviously both wireless and they generate their own power so no battery is required. This also eliminates the need for maintenance. A light comes on when you click the button showing that it has been actuated and is working. They come with the space to allow you to easily mount them and swap them around as you need. The buttons are functionally the same, but you have the option of different types of plungers depending on what works best in your situation. They're both ULl certified, rated up to 1 million operations and are IP65 sealed. They're also shock and vibration resistant making them ideal for tough industrial application. All of this is connected and powered up. It is not set up and I'll walk you through the process just to show you how easy it is for you. You'll need to connect the S8VK to power. Again it can use power from practically anywhere in the world. Then hook the output of the power supply to the input of the wireless receiver and now everything will turn on and you'll be up to the point where I am currently. Programming the buttons and the receiver doesn't require anything external like a computer, you simply set the rotary switch to the channel you want to use, move the slide switch to ID and then click the button you want to use, 3 times relatively quickly. You'll see the receive light come on indicating that the receiver got the message and it has been paired. Switch to another channel do the same thing with the other button. That's it! It's recommended to make certain other systems in the area are not in use during this procedure, however, as it may cause problems. Let's move the slider switch to run and start clicking these buttons and watch those different indicators light up. Now deleting the buttons and reassigning them is just as easy; put the rotary switched to delete and click the button three times until the light comes on. The button is now unassigned and can be programmed to another output slot. With just a few components in a couple minutes of setup you can easily integrate Omron's wireless buttons into your systems. if you want to learn more or purchase these Omron components go to Features: - 8 pushbuttons can be assigned to one receiver unit - Each receiver has 8 transistor outputs (one-shot operation) - A pushbutton can be assigned to multiple outputs of a receiver - Wireless communication is confirmed with a colored LED indicator on the pushbuttons - 922.5MHz frequency band reduces interference, providing a better signal in locations with obstacles - A high-sensitivity magnetic-base antenna is an option when installing the receiver inside a control panel

04:08

Onlinecomponents.com features Omron’s wireless buttons

02 September, 2019 Onlinecomponents.com features Omron’s wireless buttons talking about how we've made wireless communication in industrial settings extremely easy.

Innovation in panel building: new terminal and solid-state relay models with Push-In Plus technology

13 August, 2019 Reduce your workload and save space in panel building - NEW G6D-F4PU Terminal Relay & G3DZ-F4PU Terminal SSR (solid-state relay) with Push-in Plus technology.

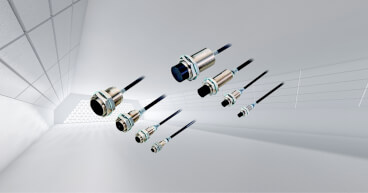

New Models of E2E NEXT Series Proximity Sensors

03 June, 2019 Sensors are equipped with IoT features to prevent stoppage and downtime.

New RX2-Series – The Driving Evolution

01 May, 2019 Versatile high-performance inverter helps maximize performance while saving energy.

New Sysmac AI Controller reduces downtime and extends equipment life

25 January, 2019 Artificial Intelligence solution collects, analyzes and utilizes data on ‘Edge’ devices within a controller to prolong equipment longevity and detects abnormalities to prevent failures.

-

Omron NX-Series Safety Network Controller

NX Series CIP Safety Controller with EtherCAT and Ethernet/IP capabilities. In addition to new hardware, Sysmac Studio new functions include Automatic Programming, Safety Data Logging, and Online Functional Test. For more information visit: USA Canada Mexico

03:22

New NX-Series Safety Network Controller

21 January, 2019 World's first* advanced safety controller to support two industrial safety networks for industrial robot systems

Ultimate flexibility to fit ever-changing production scene

12 November, 2018 OMRON introduces FHV7-series Smart Camera with World’s First Multi-color Light and 12 Megapixel Image Sensor

Committed to customer satisfaction

02 December, 2019 Customer survey shows improved satisfaction rates, development projects underway

Zero-Defect philosophy at Productronica

09 October, 2019 Omron presents its Zero-Defect solutions at the productronica 2019 in Munich.

-

The unique cobot and mobile robot hybrid concept solution from Omron

Combining a collaborative robot and mobile robot, the Mobile Manipulator hybrid concept or MoMa is a new breed of robot with all the benefits and none of the limitations of these technologies. It consists of a mobile, wheeled base, a highly dexterous collaborative robotic arm, together with integrated machine vision technology. The MoMa provides total flexibility in handling and operational mobility. It can handle various tasks including machine tending, automated kitting, assembly, packing and palletising, automated pick and retrieval as well as gluing and sealing. When part of an integrated production line, MoMa can be automatically redeployed for multiple tasks as needed, increasing flexibility in production. The future is now. ------------ SUBSCRIBE OUR CHANNEL for more!

00:55

Omron showcases Mobile Manipulator at PPMA Total Show

01 October, 2019 Omron has unveiled its vision of future industrial manufacturing at the first day of this year’s PPMA Total Show.

Omron brings the factory of the future to PPMA 2019

20 August, 2019 See our flexible production system on stand B36.

Seigo Kinugawa appointed as new CEO

14 May, 2019 Bringing a unique global perspective, Kinugawa will focus on responding to social needs with innovative manufacturing solutions.

Together we make the difference: Omron partners with Cembre in EMEA

08 April, 2019 The co-operation aims to meet the needs of panel builders, in terms of safety, consistency of control and simplification of maintenance

-

The visit of the chancellor of Germany, Angela Merkel at Omron at Hannover Messe #hm19

The Omron team was honoured to welcome the Chancellor of Germany, Angela Merkel, together with Stefan Löfven, the Prime Minister of Sweden, at our booth at Hannover Messe yesterday! ------- We demonstrated how #artificialintelligence, smart robotics, as well as advanced sensor and control technologies can change manufacturing, where humans and machines work in close cooperation to complement each other. ------ Linkedin post: SUBSCRIBE to our channel for more!

00:51

Hannover Messe: Chancellor Merkel impressed by harmonious interaction of man and machine

04 April, 2019 German Chancellor and Swedish Prime Minister meet AI-controlled table tennis robot FORPHEUS integrated with latest sensor and control technologies.

Making a business case for Artificial Intelligence

16 January, 2019 On Wednesday, December 5, around 100 professionals gathered in Malmö to attend an Omron conference about the use of artificial intelligence in the manufacturing industry.

Omron Hosts ASTM International Committee F45 Summit

18 December, 2018 The event aims to ensure productive deployment of innovative mobile robotics technology.

TM Series collaborative robots accelerate the harmonization of humans and machines

30 November, 2018 Omron has announced the global launch of the TM series collaborative robot family to realize an innovative manufacturing environment where humans and machines work in harmony.

Eight Innovation Labs offer 'proof of concept' to customers

19 October, 2018 OMRON - one of the world´s leading suppliers of industrial automation– is proud to open the doors of eight new Innovation Labs in Europe.

-

ŠKODA AUTO uses Omron's fully autonomous LD mobile robot at Vrchlabí plant

The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

03:00